The promise of wearables, functional fabrics, the Internet of Things, and their “next-generation” technological cohort seems tantalizingly within reach. But researchers in the field will tell you a prime reason for their delayed “arrival” is the problem of seamlessly integrating connection technology — namely, antennas — with shape-shifting and flexible “things.”

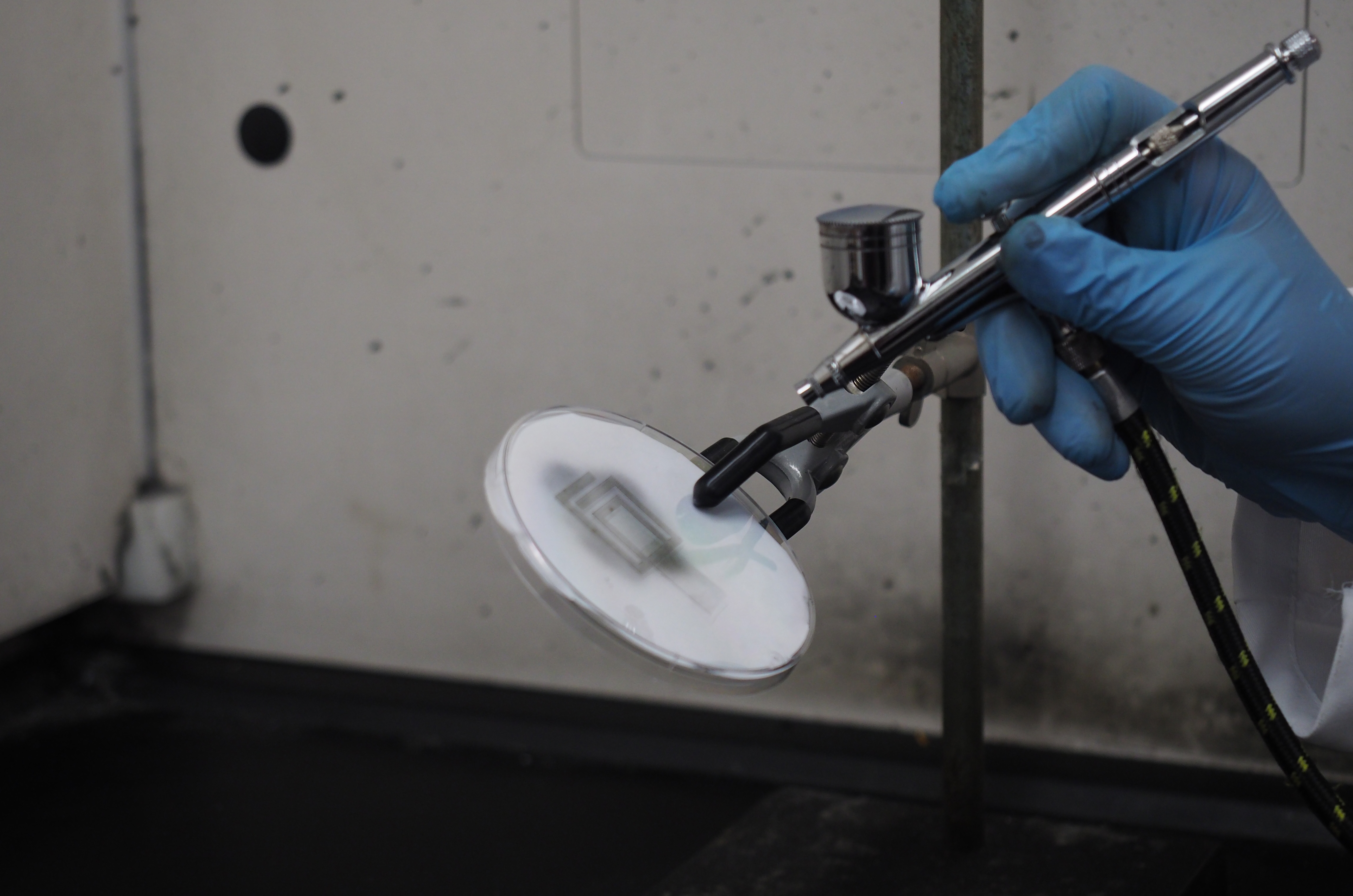

But a breakthrough by researchers in Drexel’s College of Engineering, could now make installing an antenna as easy as applying some bug spray.

In research recently published in Science Advances, the group reports on a method for spraying invisibly thin antennas, made from a type of two-dimensional, metallic material called MXene, that perform as well as those being used in mobile devices, wireless routers and portable transducers.

“This is a very exciting finding because there is a lot of potential for this type of technology,” said Kapil Dandekar, a professor of Electrical and Computer Engineering in the College of Engineering, who directs the Drexel Wireless Systems Lab, and was a co-author of the research. “The ability to spray an antenna on a flexible substrate or make it optically transparent means that we could have a lot of new places to set up networks — there are new applications and new ways of collecting data that we can’t even imagine at the moment.”

Spray-applied MXene antennas could open the door for new applications in smart technology, wearables and IoT devices.

The researchers, from the College’s Department of Materials Science and Engineering, report that the MXene titanium carbide can be dissolved in water to create an ink or paint. The exceptional conductivity of the material enables it to transmit and direct radio waves, even when it’s applied in a very thin coating.

“We found that even transparent antennas with thicknesses of tens of nanometers were able to communicate efficiently,” said Asia Sarycheva, a doctoral candidate in the A.J. Drexel Nanomaterials Institute and Materials Science and Engineering Department. “By increasing the thickness up to 8 microns, the performance of MXene antenna achieved 98 percent of its predicted maximum value.”

Preserving transmission quality in a form this thin is significant because it would allow antennas to easily be embedded — literally, sprayed on — in a wide variety of objects and surfaces without adding additional weight or circuitry or requiring a certain level of rigidity.

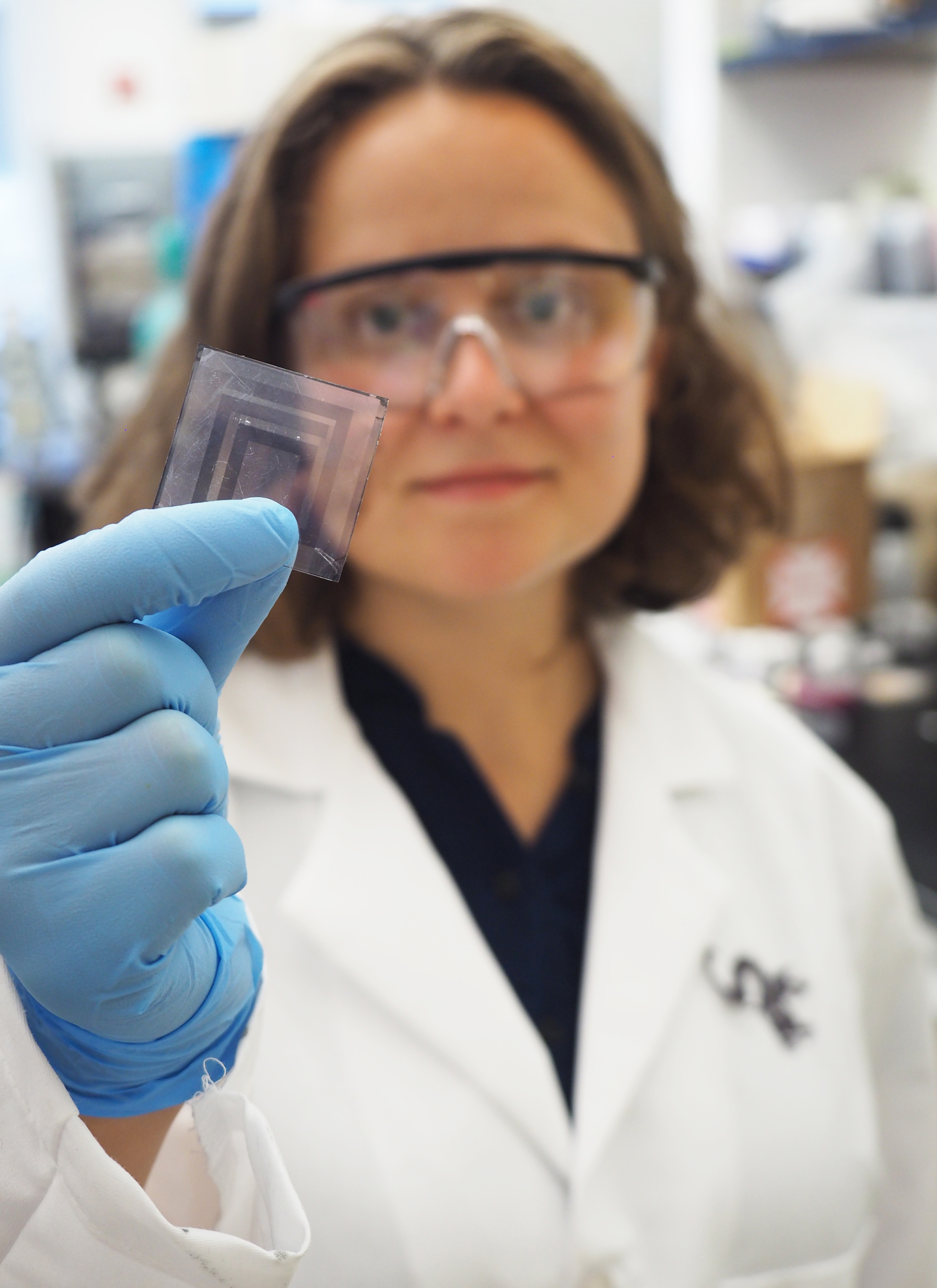

Researchers in the College of Engineering developed and tested spray-applied antennas made from a type of two-dimensional material called MXene.

“This technology could enable the truly seamless integration of antennas with everyday objects which will be critical for the emerging Internet of Things,” Dandekar said. “Researchers have done a lot of work with non-traditional materials trying to figure out where manufacturing technology meets system needs, but this technology could make it a lot easier to answer some of the difficult questions we’ve been working on for years.”

Initial testing of the sprayed antennas suggest that they can perform with the same range of quality as current antennas, which are made from familiar metals, like gold, silver, copper and aluminum, but are much thicker than MXene antennas. Making antennas smaller and lighter has long been a goal of materials scientists and electrical engineers, so this discovery is a sizable step forward both in terms of reducing their footprint as well as broadening their application.

“Current fabrication methods of metals cannot make antennas thin enough and applicable to any surface, in spite of decades of research and development to improve the performance of metal antennas,” said Yury Gogotsi, PhD, Distinguished University and Bach professor of Materials Science and Engineering in the College of Engineering, and Director of the A.J. Drexel Nanomaterials Institute, who initiated and led the project. “We were looking for two-dimensional nanomaterials, which have sheet thickness about hundred thousand times thinner than a human hair; just a few atoms across, and can self-assemble into conductive films upon deposition on any surface. Therefore, we selected MXene, which is a two-dimensional titanium carbide material, that is stronger than metals and is metallically conductive, as a candidate for ultra-thin antennas.”

Naturally MXene materials have drawn comparisons to promising two-dimensional materials like graphene, which won the Nobel Prize in 2010 and has been explored as a material for printable antennas. In the paper, the Drexel researchers put the spray-on antennas up against a variety of antennas made from these new materials, including graphene, silver ink and carbon nanotubes. The MXene antennas were 50 times better than graphene and 300 times better than silver ink antennas in terms of preserving the quality of radio wave transmission.

“The MXene antenna not only outperformed the macro and micro world of metal antennas, we went beyond the performance of available nanomaterial antennas, while keeping the antenna thickness very low,” said Babak Anasori, PhD, a research assistant professor in A.J. Drexel Nanomaterials Institute. “The thinnest antenna was as thin as 62 nanometers — about thousand times thinner than a sheep of paper — and it was almost transparent. Unlike other nanomaterials fabrication methods, that requires additives, called binders, and extra steps of heating to sinter the nanoparticles together, we made antennas in a single step by airbrush spraying our water-based MXene ink.”

The group initially tested the spray-on application of the antenna ink on a rough substrate — cellulose paper — and a smooth one — polyethylene terephthalate sheets — the next step for their work will be looking at the best ways to apply it to a wide variety of surfaces from glass to yarn and skin.

“Further research on using materials from the MXene family in wireless communication may enable fully transparent electronics and greatly improved wearable devices that will support the active lifestyles we are living,” Anasori said.

Source: https://drexel.edu

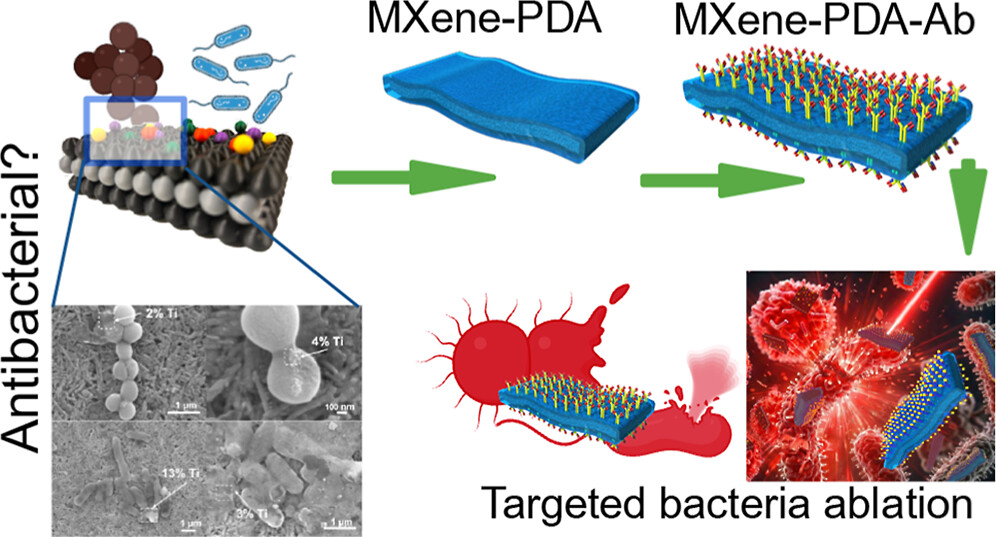

Do MXene nanosheets possess intrinsic antibacterial activity? A systematic study of high-quality Ti-, V-, and Nb-based MXenes reveals negligible inherent antimicrobial effects while highlighting their strong potential for targeted photothermal antibacterial therapy.

Do MXene nanosheets possess intrinsic antibacterial activity? A systematic study of high-quality Ti-, V-, and Nb-based MXenes reveals negligible inherent antimicrobial effects while highlighting their strong potential for targeted photothermal antibacterial therapy. Highlights

Highlights We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development.

We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development. Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments.

Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments. Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

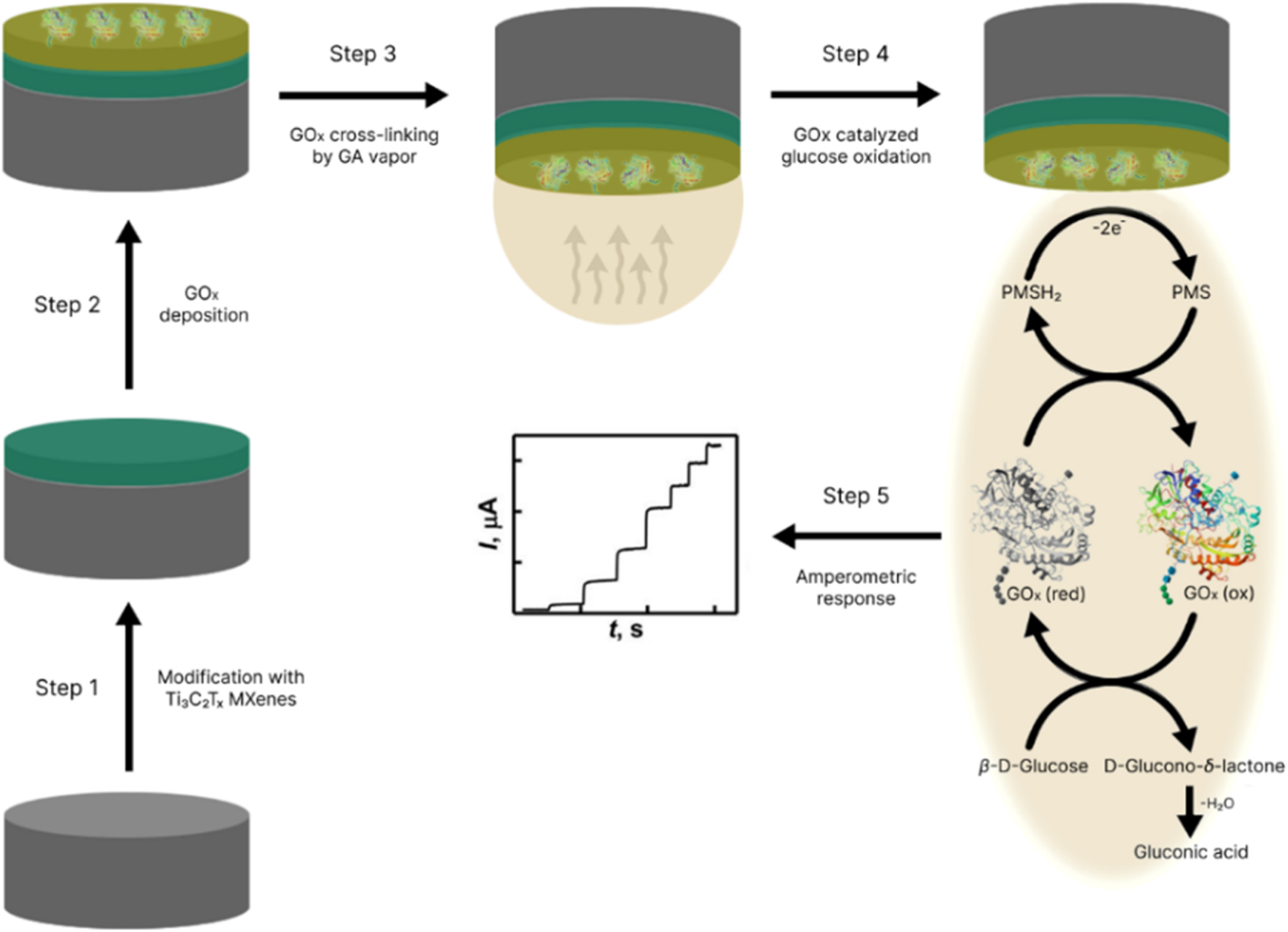

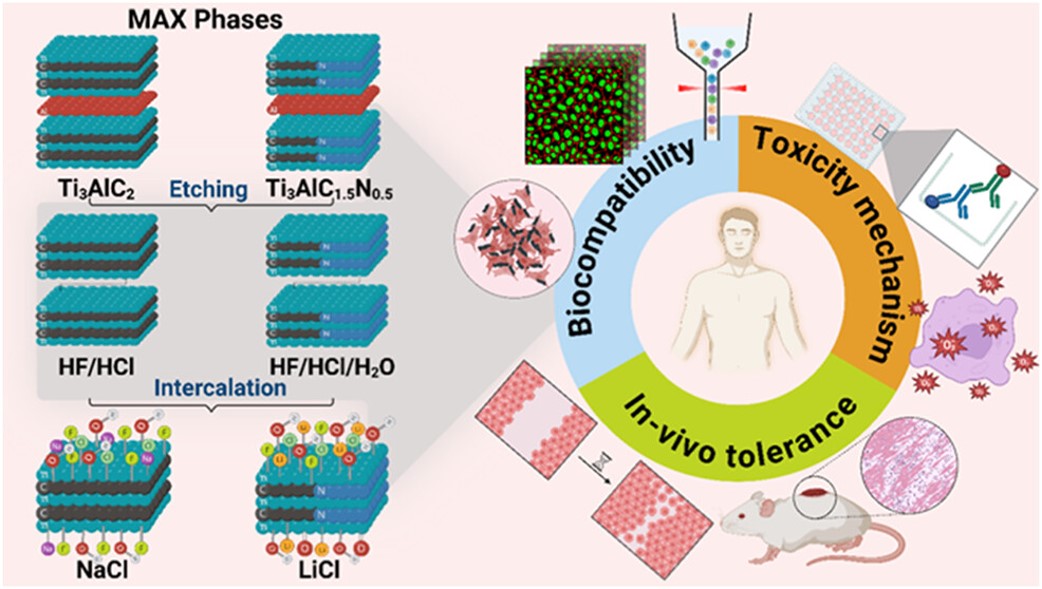

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications.

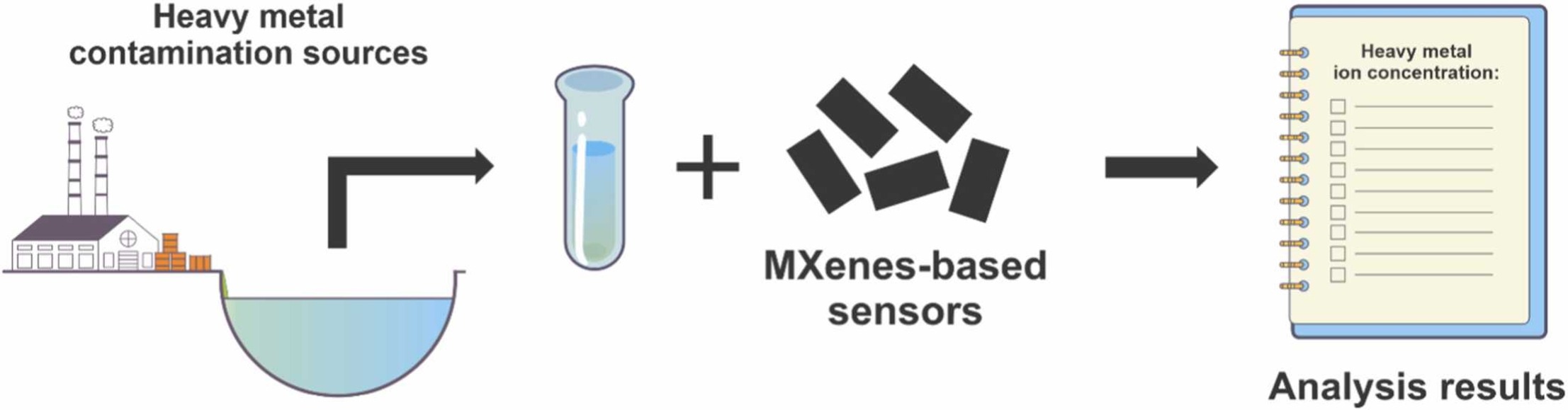

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications. An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme.

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme. Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved!

Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved! Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!

Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!  Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field!

Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field! We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A.

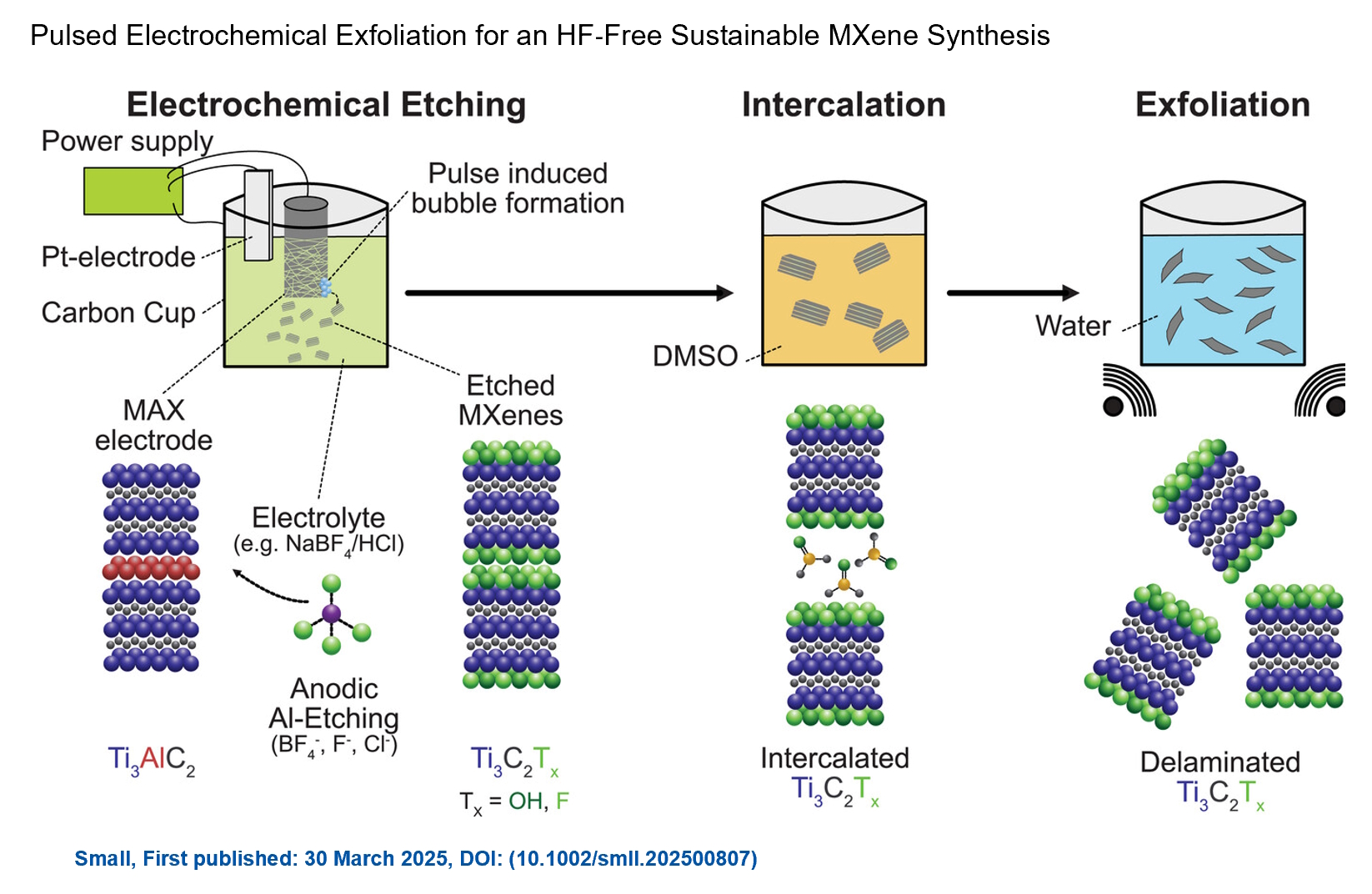

We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A. Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.

Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.