Using of additional opportunities of CAD specialized program products – the software intended for development of drawings, engineering and technological documentation as well as 3D models. CAD is computer-aided design system to draw in CAE – designing of 3D solids, CAM – systems of engineering calculations enables our engineers to solve non-standard tasks of any complexity, is the use of computer software to control machine tools and related machinery in the manufacturing of workpieces . Comp uter-aided design (CAD) is program technologies for designing of 2D and 3D shape of the objects. It’s widely used in lots of spheres, in particular, animation, automobiles, shipbuilding, aerospace industry, industrial and architectural design and so forth. CAD is the main driving force to explore in the field of computational geometry, computer graphics (both hardware and software) as well as discrete differential geometry.

uter-aided design (CAD) is program technologies for designing of 2D and 3D shape of the objects. It’s widely used in lots of spheres, in particular, animation, automobiles, shipbuilding, aerospace industry, industrial and architectural design and so forth. CAD is the main driving force to explore in the field of computational geometry, computer graphics (both hardware and software) as well as discrete differential geometry.

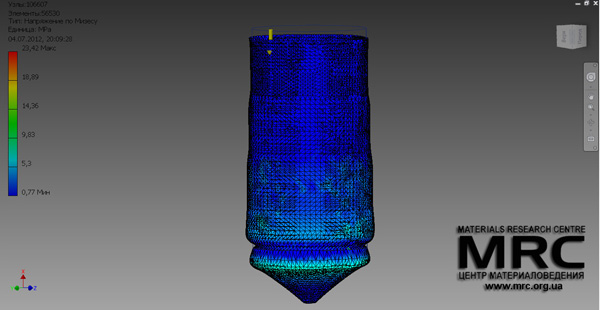

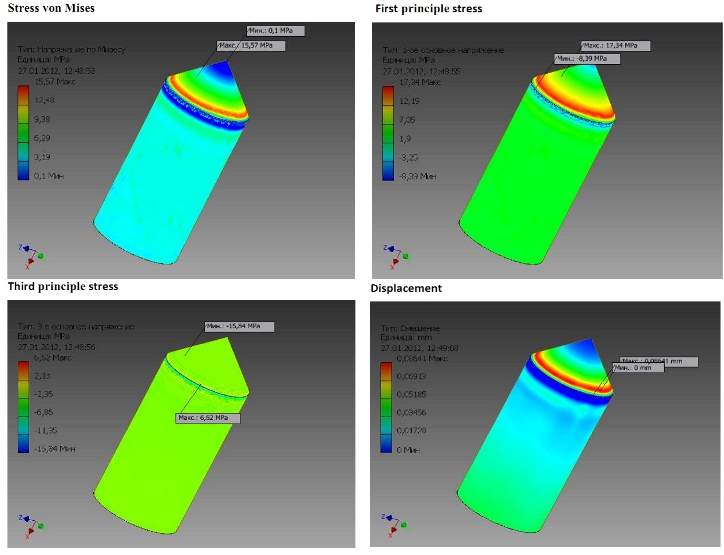

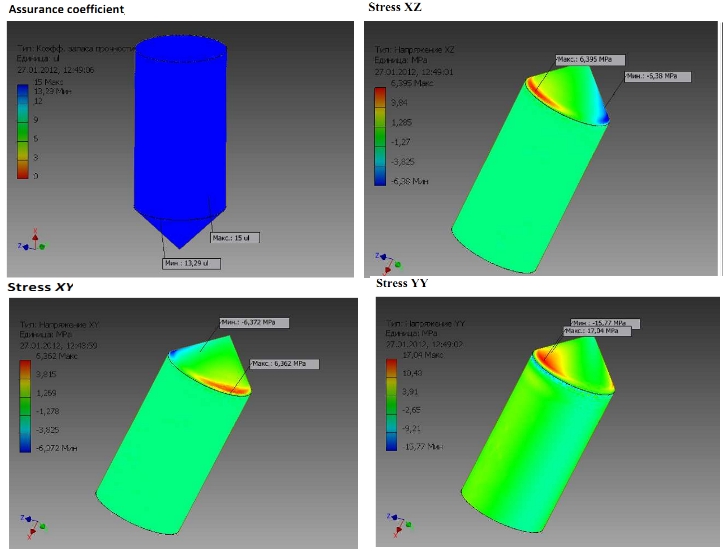

Up-to-date systems of engineering calculations (CAE) are usually applied along with CAD systems. CAE systems are the major providers of information to help support design teams in decision making.CAE areas covered include: Stress analysis on components and assemblies using Finite Element Analysis; еhermal and fluid flow analysis, сomputational fluid dynamics; multibody dynamics and kinematics; analysis tools for process simulation for operations, product or process optimization.

Methods applied for engineering calculations:

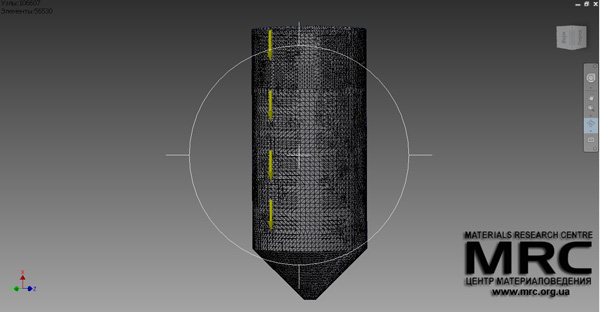

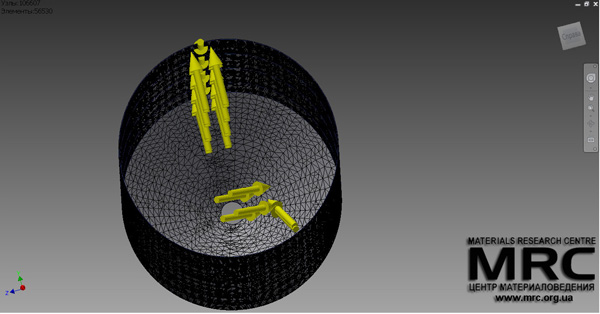

Finite element method. - The basic idea in the finite element method is to find solution of a complicated problem by replacing it by a simpler one. Since the actual problem is replaced by a simpler one in finding the solution, it would be possible to find only an approximate solution rather than the exact solution. Moreover, in the finite element method, it will often be possible to improve or refine the approximate solution by spending more computational effort. For the last decades this method is the leading one and widely applied.

Finite difference method is a well-known and simplest method of interpolation. It is used to solve ordinary differential equations that have conditions imposed on the boundary rather than at the initial point.

Finite difference method is a well-known and simplest method of interpolation. It is used to solve ordinary differential equations that have conditions imposed on the boundary rather than at the initial point.

The finite-volume method is a method for representing and evaluating partial differential equations in the form of algebraic equations. In the finite volume method, volume integrals in a partial differential equation that contain a divergence term are converted to surface integrals, using the divergence theorem. These terms are then evaluated as fluxes at the surfaces of each finite volume.

|

|

The von Mises stress is often used in determining whether an isotropic and ductile metal will yield when subjected to a complex loading condition. This is accomplished by calculating the von Mises stress and comparing it to the material's yield stress, which constitutes the von Mises Yield Criterion.

The objective is to develop a yield criterion for ductile metals that works for any complex 3-D loading condition, regardless of the mix of normal and shear stresses. The von Mises stress does this by boiling the complex stress state down into a single scalar number that is compared to a metal's yield strength, also a single scalar numerical value determined from a uniaxial tension test (because that's the easiest) on the material in a lab.Hydrostatic and deviatoric stresses.The hydrostatic stress is related to volume change, while the deviatoric stress is related to shape change.

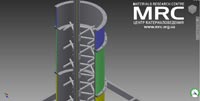

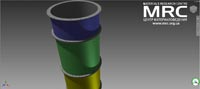

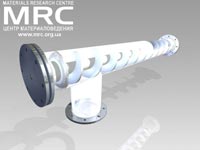

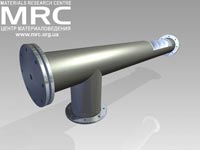

Materials Research Centre uses Autodesk Inventor 3D CAD software products, that offer a comprehensive, flexible set of software for 3D mechanical design, product simulation, tooling creation, engineer to order, and design communication. Inventor takes engineer beyond 3D to Digital Prototyping by enabling him to produce an accurate 3D model that can help to design, visualize, and simulate products before they are built. Digital Prototyping with Inventor helps companies design better products, reduce development costs, and get to market faster.

Autodesk Inventor comes in different product configurations that offer specific levels of functionality to fit every design needs. Inventor is powerful 3D CAD Software for Mechanical Design. Autodesk Inventor 3D mechanical design software includes CAD productivity and design communication tools that can help to reduce errors, communicate more effectively, and deliver more innovative product designs faster. The Inventor model is an accurate 3D digital prototype that can validate the form, fit, and function of a design and unites direct modeling and parametric workflows.

|

|

|

|

3D models of equipment by Autodesk Inventor |

||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

all 3D models can be divided into two categories:

Solid - These models define the volume of the object they represent, they are mostly used for nonvisual simulations such as medical and engineering simulations, for CAD and specialized visual applications

Shell/boundary - these models represent the surface, the boundary of the object, not its volume

Materials Research Centre is actively supporting using of CAD with open source code for multifunctional operation environment GNU/Linux assembled under the model of free and open source software. In order to develop engineering documentation (2D and 3D design drawings) co-workers of the Materials Research Centre’s Design Department use specialized software on the basis of multifunctional operation environment GNU/Linux. It is used as operation system of the most powerful supercomputers all over the world (servers, computers of non-standard architecture due to the opportunity of OS kernel quick adaptation and varieties of the software, military systems, computers mounted in various devices due to wide range of opportunities on Linux configuring with a task being performed.

Freeware is being actively used for design and engineering calculation. It’s a wide range of software with right of the user for unlimited installation, launching as well as easy use, study, distribution, changing (upgrading) and open-source software. This is the software with open-source code, available for browsing, study and upgrading which requires additional qualification but allows to update the most open program, as well as to use code for creating new programs, updating and correction of mistakes.

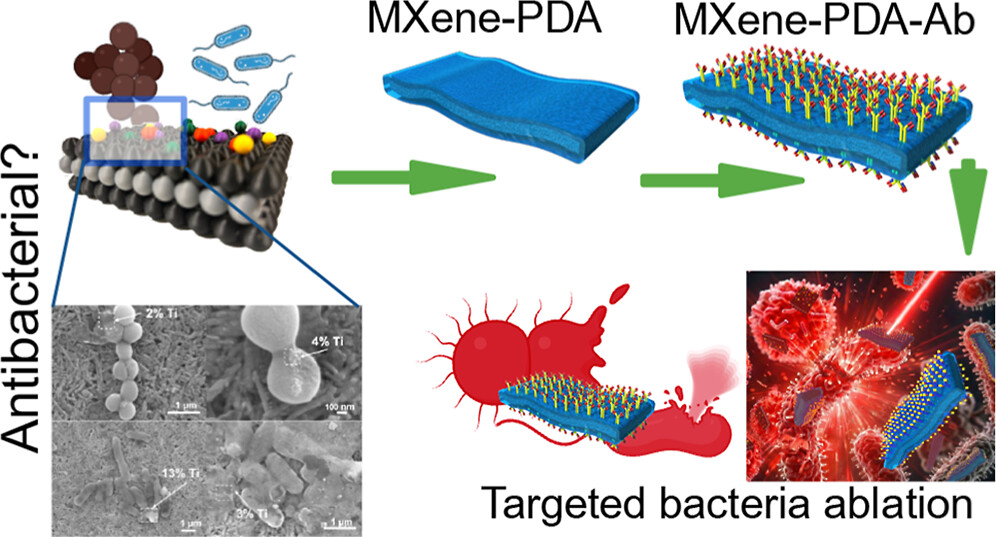

Do MXene nanosheets possess intrinsic antibacterial activity? A systematic study of high-quality Ti-, V-, and Nb-based MXenes reveals negligible inherent antimicrobial effects while highlighting their strong potential for targeted photothermal antibacterial therapy.

Do MXene nanosheets possess intrinsic antibacterial activity? A systematic study of high-quality Ti-, V-, and Nb-based MXenes reveals negligible inherent antimicrobial effects while highlighting their strong potential for targeted photothermal antibacterial therapy. Highlights

Highlights We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development.

We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development. Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments.

Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments. Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

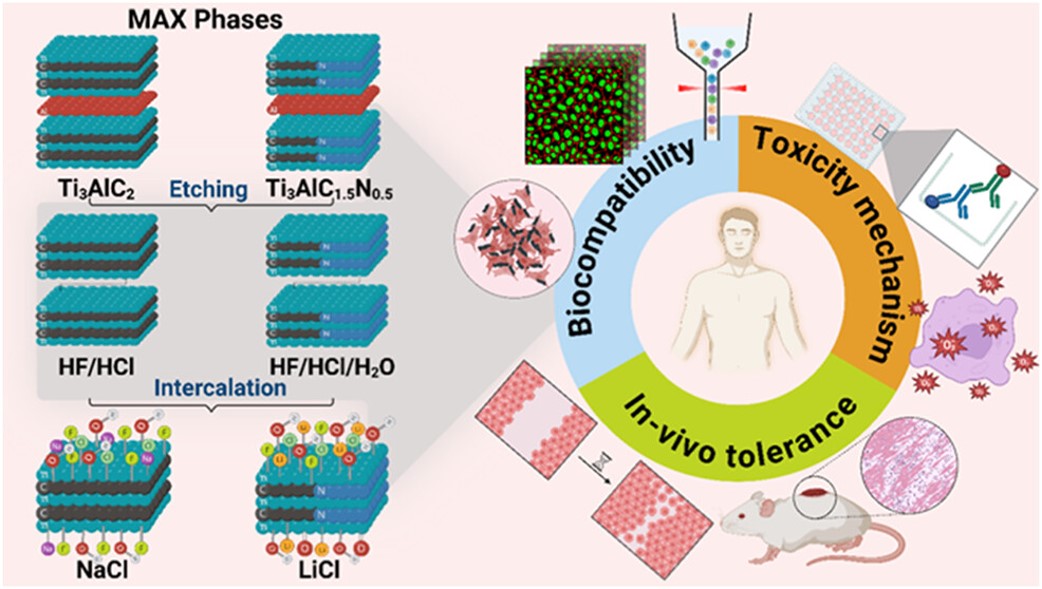

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications.

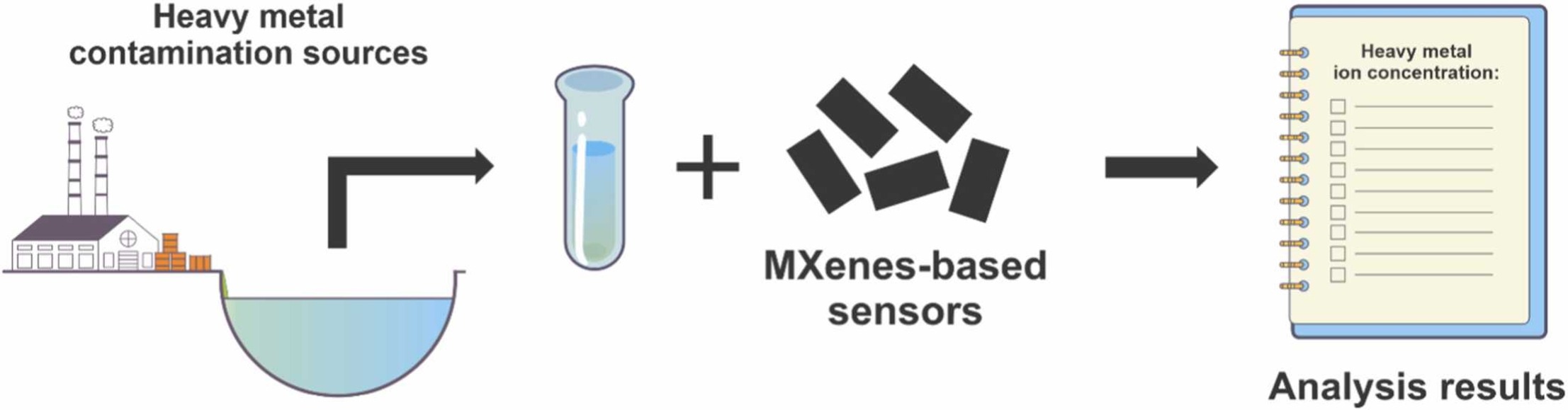

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications. An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme.

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme. Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved!

Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved! Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!

Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!  Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field!

Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field! We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A.

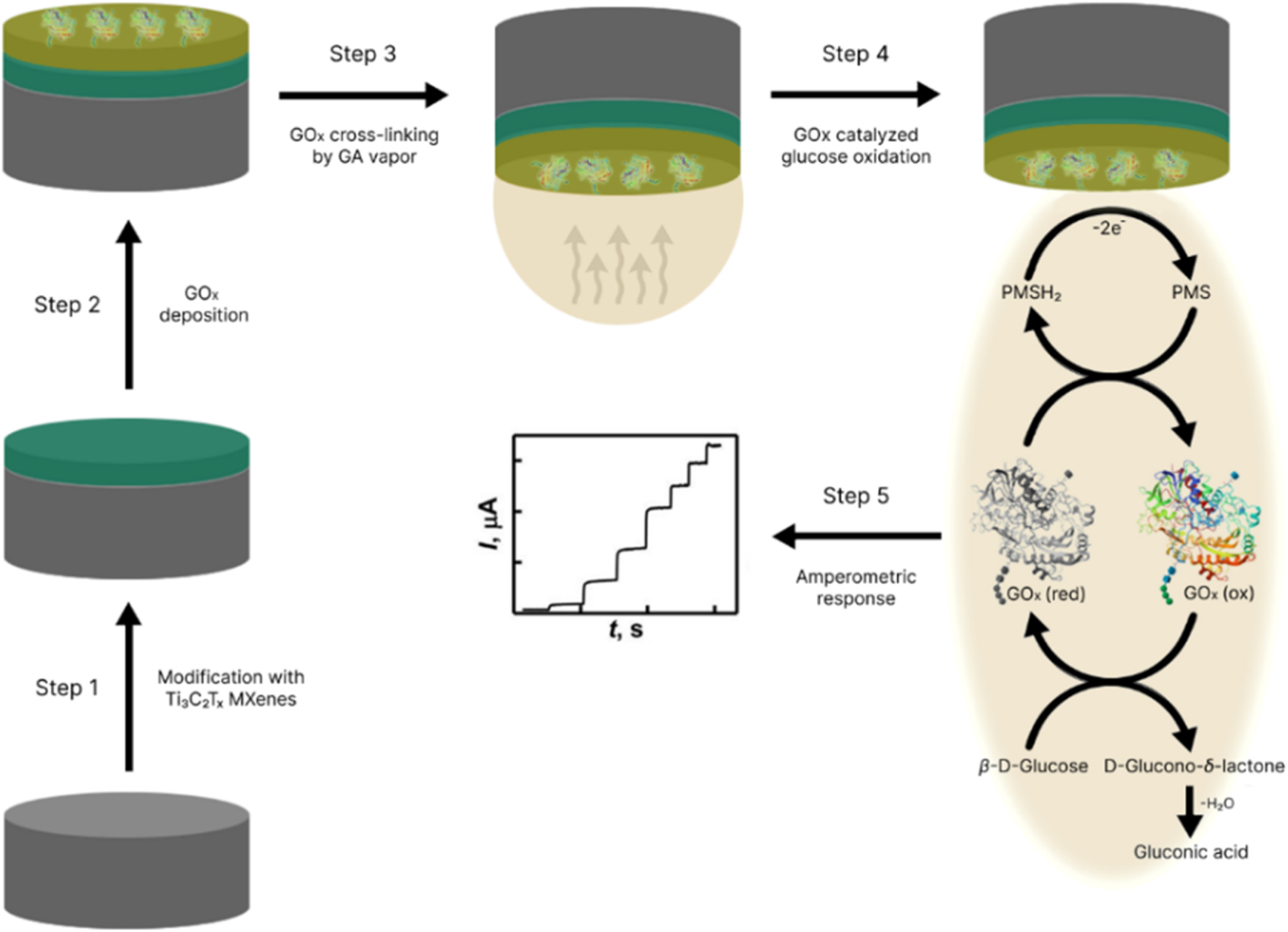

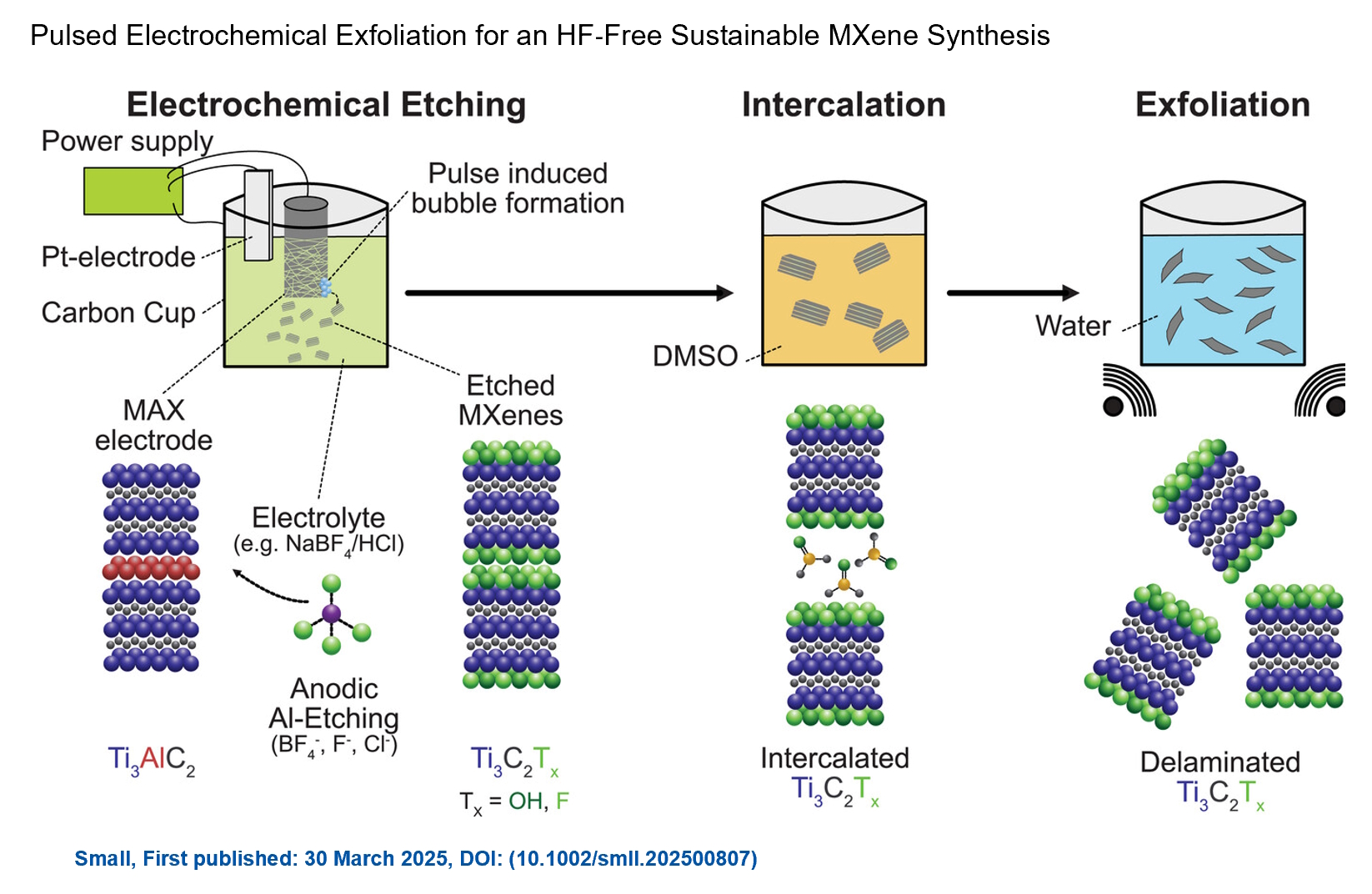

We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A. Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.

Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.