|

This new technology, dubbed the “electrochemical flow capacitor,” stores energy in the same way as a supercapacitor, but is much less costly to scale up for large, industrial applications. Results from the team’s most recent study were published in a special issue of Advanced Energy Materials ("The Electrochemical Flow Capacitor: A New Concept for Rapid Energy Storage and Recovery") focusing on next-generation batteries.

The electrochemical flow capacitor uses a flow cell architecture, similar to existing redox flow batteries for grid storage, consisting of an electrochemical cell connected to external electrolyte reservoirs. However, this technology is unique in that it uses a flowable slurry of capacitive particles suspended in a liquid electrolyte carrier fluid. Uncharged slurry is pumped through a flow cell, where energy is stored capacitively within the solid particles.The charged slurry can then be held in reservoirs until the energy is needed, at which time the entire process is reversed. By utilizing this capacitive slurry instead of conventional battery electroly tes, the Drexel team says that its new design can be operated in high power applications for hundreds of thousands of charge-discharge cycles, vital for industrial applications

llustration by Kristy Jost, PhD student of Materials Science and Engineering.

“It is well known that conventional supercapacitors provide very high power output with minimal degradation in performance. However, they have always had fairly limited energy storage capacity”, said Dr. Yury Gogotsi, distinguished university professor and Trustee Chair of Materials Science and Engineering and director of the A.J. Drexel Nanotechnology Institute at Drexel University, one of the lead scientists on the project. “By incorporating the active material of supercapacitors into a fluid, we are able to address issues of capacity and scalability by adopting the system architecture from redox flow batteries”.

Dr. E. C. Kumbur, Director of the Electrochemical Energy Systems Laboratory at Drexel states: “Flow battery architecture is very attractive for grid-scale applications because it allows for scalable energy storage by decoupling the power and energy storage.” In flow battery systems, as well as the electrochemical flow capacitor, the energy storage capacity is determined by the size of the reservoirs which store the charged material. If a larger capacity is desired, the tanks can simply be scaled up in size. Similarly, the power output of the system is controlled by the size of the electrochemical cell, with larger cells producing more power.

“Slow response rate is a common problem for most energy storage systems. Incorporating the rapid charging and discharging ability of supercapacitors into this architecture is a major advantage to effectively store the fluctuating energy sources and deliver the energy rapidly as needed,” Kumbur said. “Electrical energy storage is the bottleneck for more widespread implementation of renewable energy sources like wind and solar,” said Dr. Volker Presser, Assistant Research Professor in the Department of Materials Science and Engineering at Drexel. “We believe that this new technology has important applications in that field. Moreover, these technologies can also be used to enhance the efficiency of existing power sources, and improve the stability of the grid.”

The team’s ongoing work is focused on developing new slurry compositions based on different carbon nanomaterials and electrolytes, as well as optimizing their flow capacitor design.

“We have observed very promising performance so far, but this is by no means the upper limit of this technology,” Gogotsi said. The team is also designing a small demonstration prototype to illustrate the fundamental operation of the system. Materials Research Centre also participates in development of the pilot device with flow electrochemical capacitor.

Source: Drexel University

Highlights

Highlights We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development.

We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development. Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments.

Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments. Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

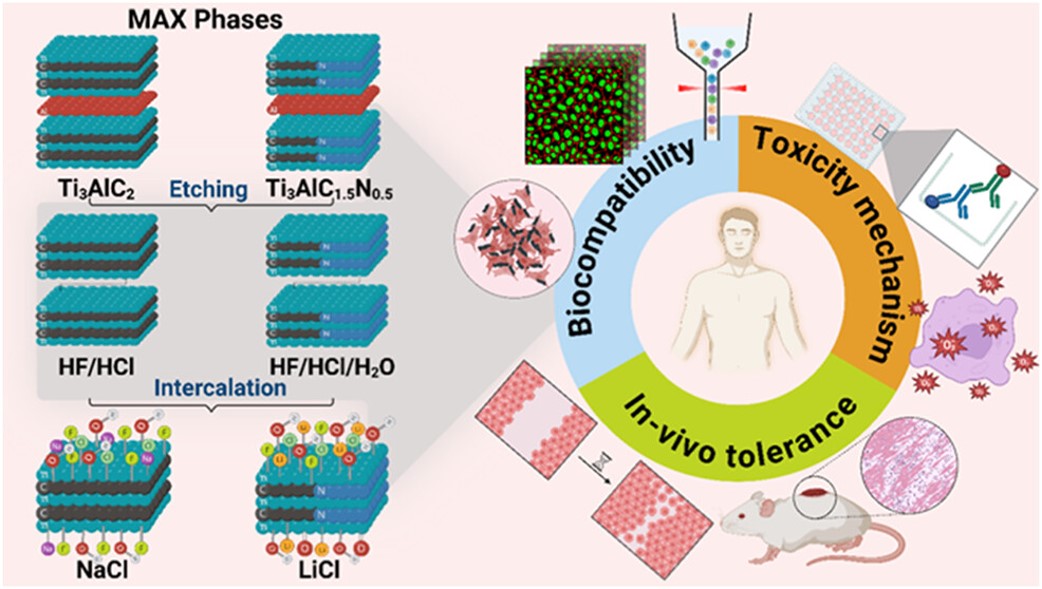

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications.

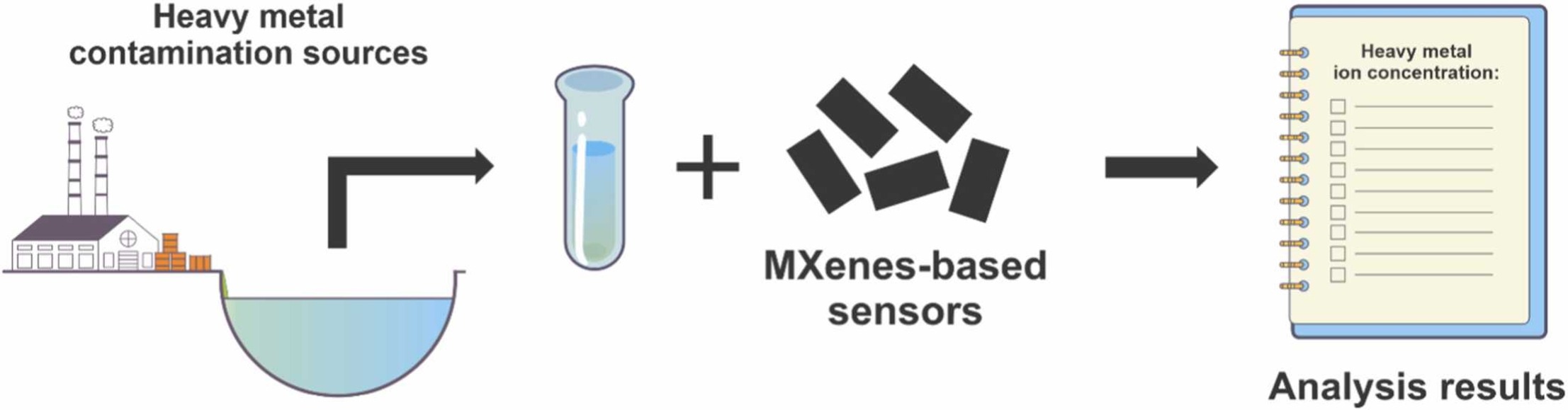

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications. An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme.

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme. Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved!

Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved! Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!

Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!  Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field!

Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field! We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A.

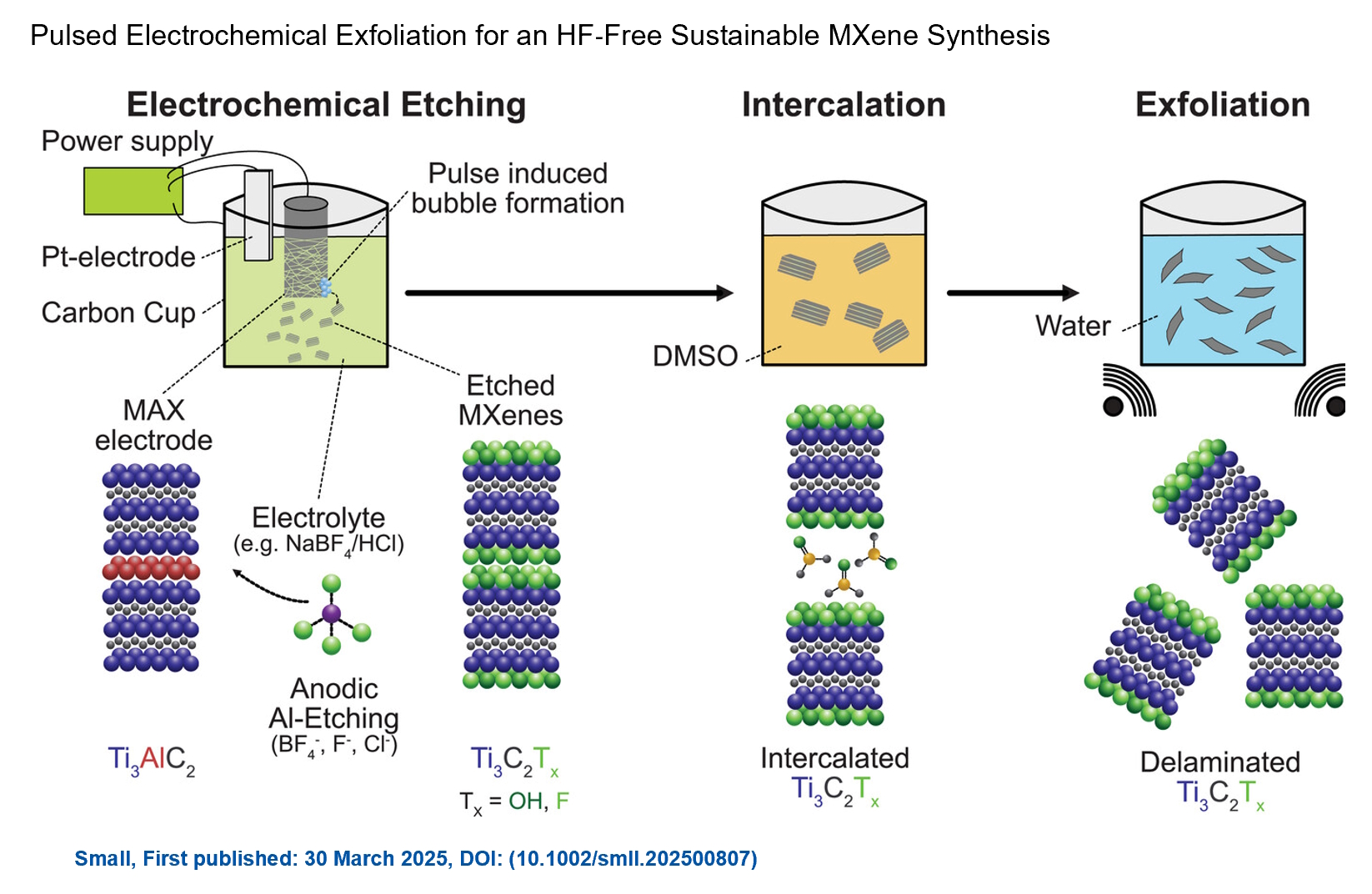

We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A. Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.

Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved. Congratulations to all collaborators with this interesting joint work!

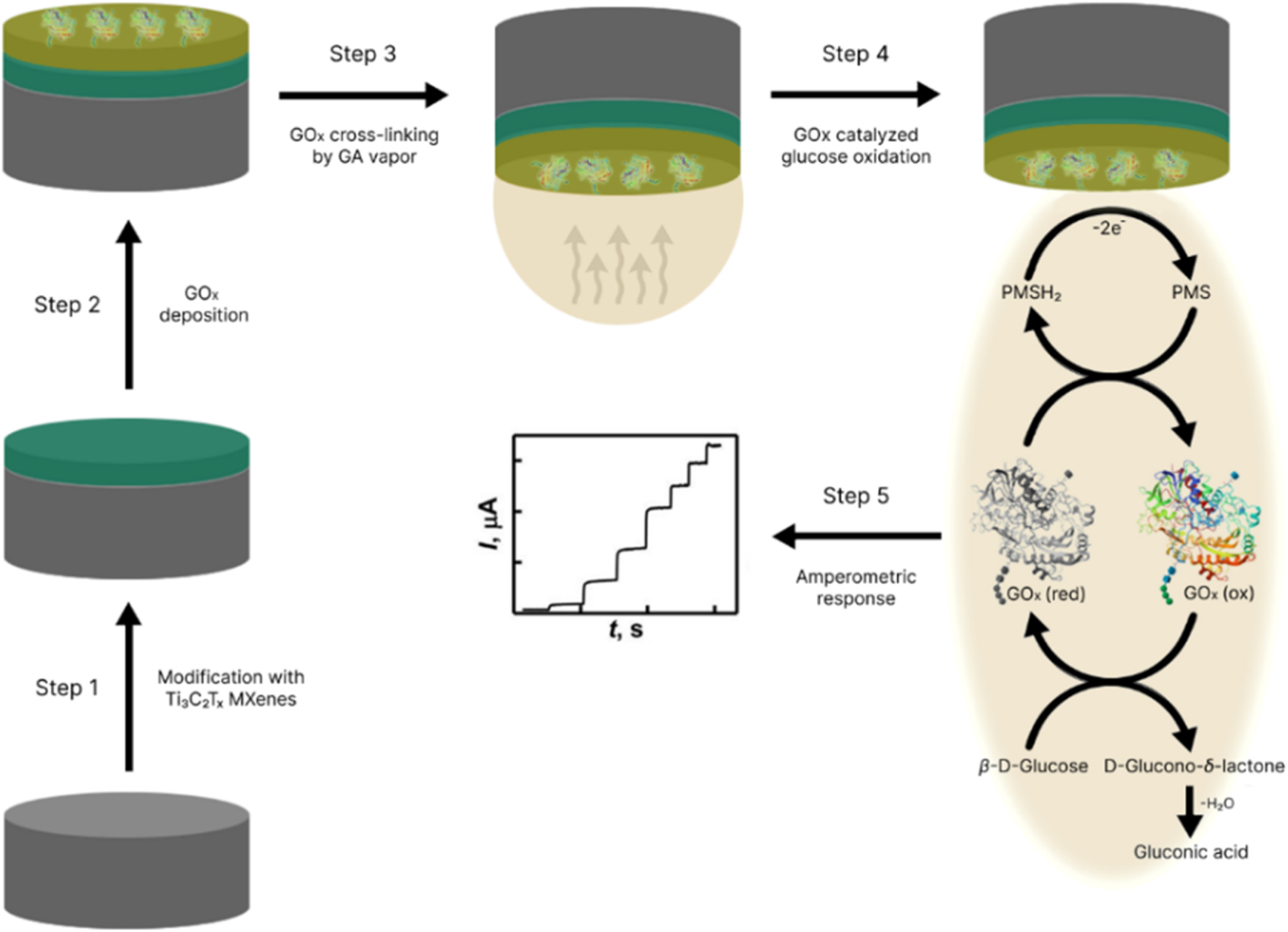

Congratulations to all collaborators with this interesting joint work!