Increasing thickness of coarse-grained carbon electrodes for high device capacitance

Oleksiy Gogotsi a, b*, Vladimir Izotov c, d, Xuehang Wang e, Dmytro Havrykovc, Illia Koltsov a,c, Wei Han c,d, Alla Serhienko a, Ivan Hrysko a, Yulia Zozulya a, Olga Linyucheva a, Vitaliy Balitskiy a, Veronika Zahorodna a,b, Yury Gogotsi d,e

a Materials Research Center, Kiev 03680, Ukraine

b National Metallurgical Academy of Ukraine, Dnipro 49600, Ukraine

c International Center of Future Science, Jilin University, Changchun, 130012, P.R. China

d Key Laboratory of Physics and Technology for Advanced Batteries (Ministry of Education), College of Physics, Jilin University, Changchun 130012, P.R. China

e A. J. Drexel Nanomaterials Institute, and Department of Materials Science and Engineering, Drexel University, Philadelphia, Pennsylvania 19104, United States

Corresponding author: Этот e-mail адрес защищен от спам-ботов, для его просмотра у Вас должен быть включен Javascript

Abstract

The main shortcoming of modern supercapacitors is their low specific capacitance. The main issue that engineers and scientists designing supercapacitors are facing with is to find the ways how to improve specific capacitance and increase the energy density of devices.

One way to enhance the specific capacity is by increasing the content of the active material (porous carbon and electrolyte) relative to passive materials (separator, binder, current collectors and packaging) in supercapacitor electrodes.

The increase of active materials in the electrodes and maintaining their electrochemical and mechanical properties at the same time, in practice can be achieved by using thicker electrodes without changing the current collectors or separators.

However, a saturation effect leads to a decrease in specific capacitance with increasing electrode thickness. Also, to maintain the mechanical properties of thick electrodes, it is necessary to increase the content of the binder, which leads to a decrease in the concentration of the active material. Passive materials do not contribute to the energy storage by the supercapacitor but affect its specific characteristics.

Herein we report about the effect of all the above factors on the specific capacitance of supercapacitor devices.

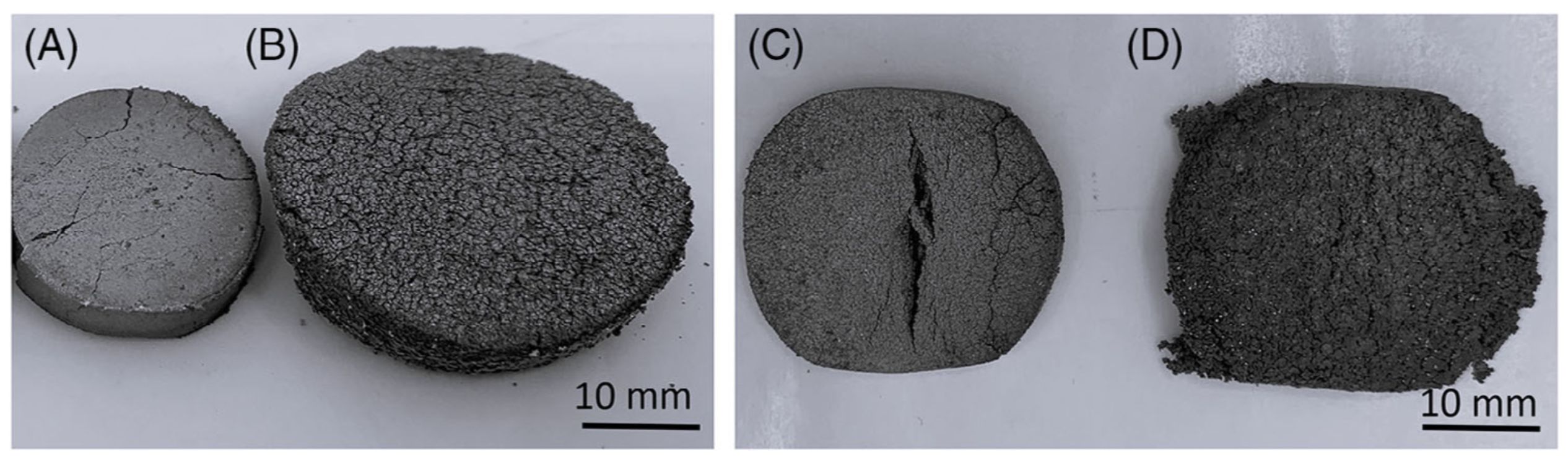

We show that electrodes with up to 1 mm thickness (compared to 50-200 microns in commercial devices) can be manufactured when coarse-grained activated or carbide-derived carbon is used.

An analytical expression connecting the dimensions of passive elements of the electrochemical system and the parameters describing the specific capacitance as a function of thickness of the carbon electrode is obtained. Experimental studies of the dependence of specific capacitance on the thickness of carbon-based electrodes have been carried out.

The obtained experimental data are in good agreement with the model predictions.

References

[1] P. Simon, Y. Gogotsi, Materials for electrochemical capacitors, Nat. Mater. 7 (2008), p. 84

[2] Dyatkin, O. Gogotsi, B. Malinovskiy, Y. Zozulya, P. Simon, Y. Gogotsi, High capacitance of coarse-grained carbide derived carbon electrodes. J. Power Sources 306 (2016), pp. 32-41.

[3] C. Portet, G. Yushin, Y. Gogotsi, Effect of carbon particle size on electrochemical performance of EDLC, J. Electrochem. Soc. 155 (2008), pp. A531-A536.

[4] B. Dyatkin, O. Gogotsi, Y. Zozuly, B. Malinovskiy, P. Simon, Y. Gogotsi. High Capacitance of Coarse-Grained Carbide-Derived Carbon Particles. Abstract Book of the 4th International Symposium on Enhanced Electrochemical Capacitors, June 8-12 2015, Montpelier, France, p. 143.

Acknowledgement. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 690853.

| 2018 IEEE 8th International Conference on Nanomaterials: Applications & Properties, September 09-14, 2018 |

|

|

At the poster session of the conference Oleksiy Gogotsi presented two poster presentations on advanced nanomaterials for different applications, prepared with colleagues from Drexel University, USA, and Jilin University, China

At the poster session of the conference Oleksiy Gogotsi presented two poster presentations on advanced nanomaterials for different applications, prepared with colleagues from Drexel University, USA, and Jilin University, China

Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field!

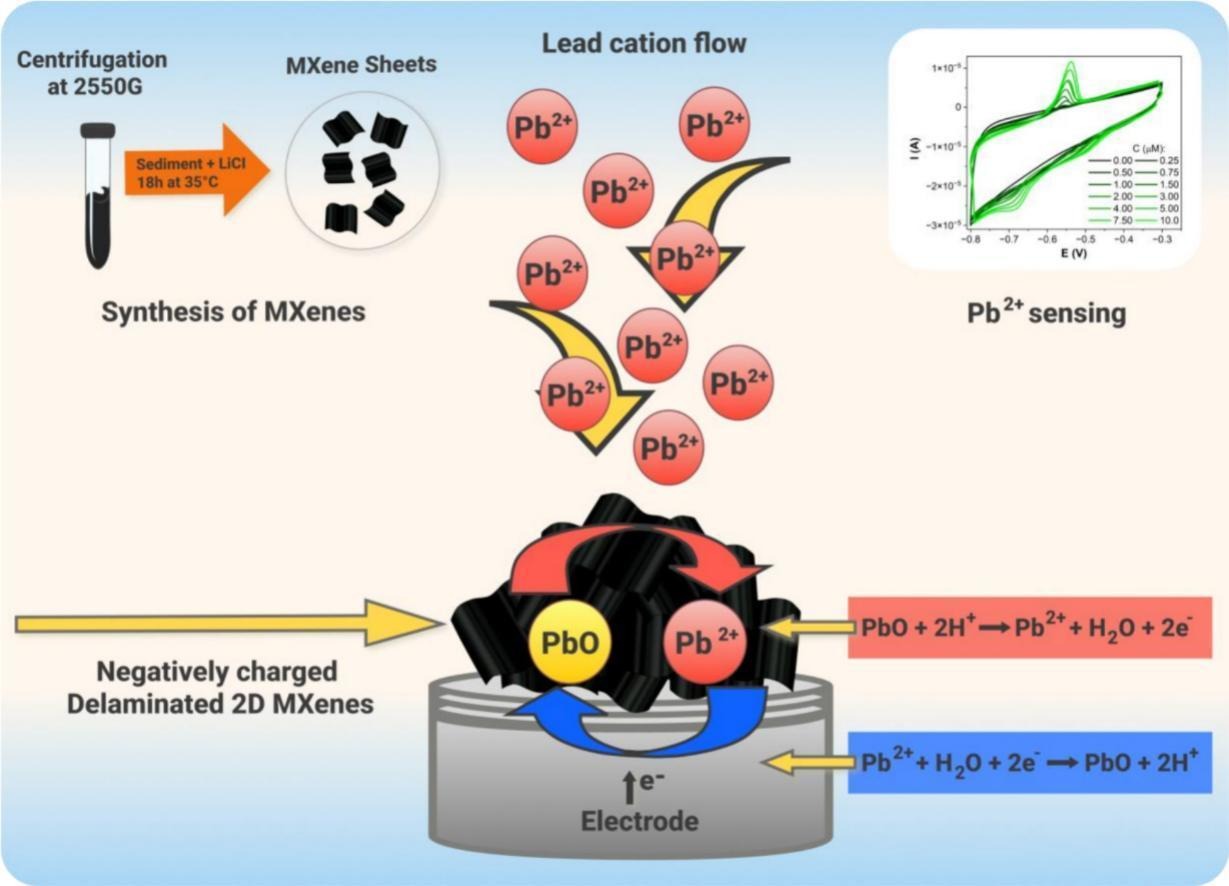

Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field! We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A.

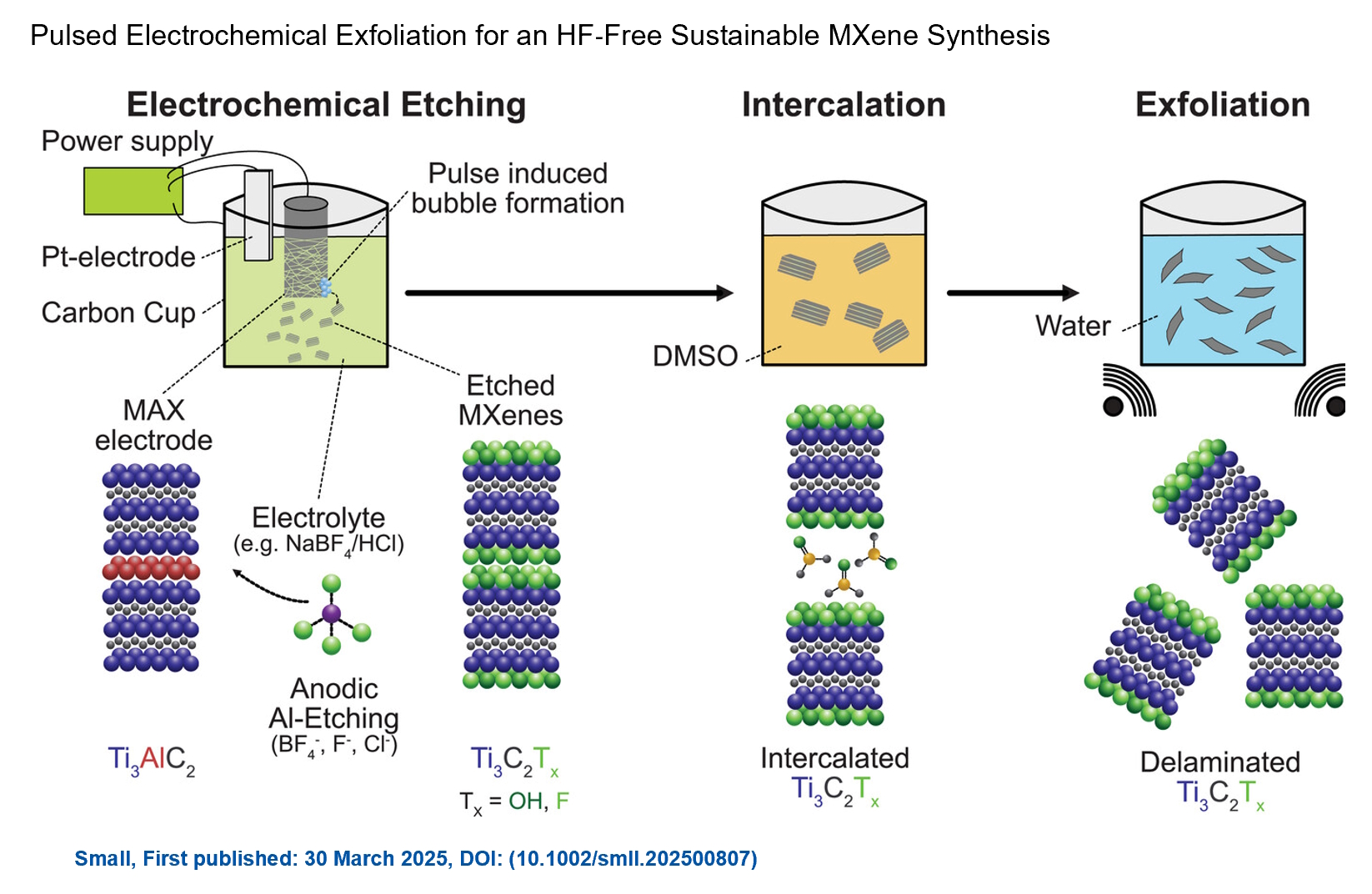

We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A. Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.

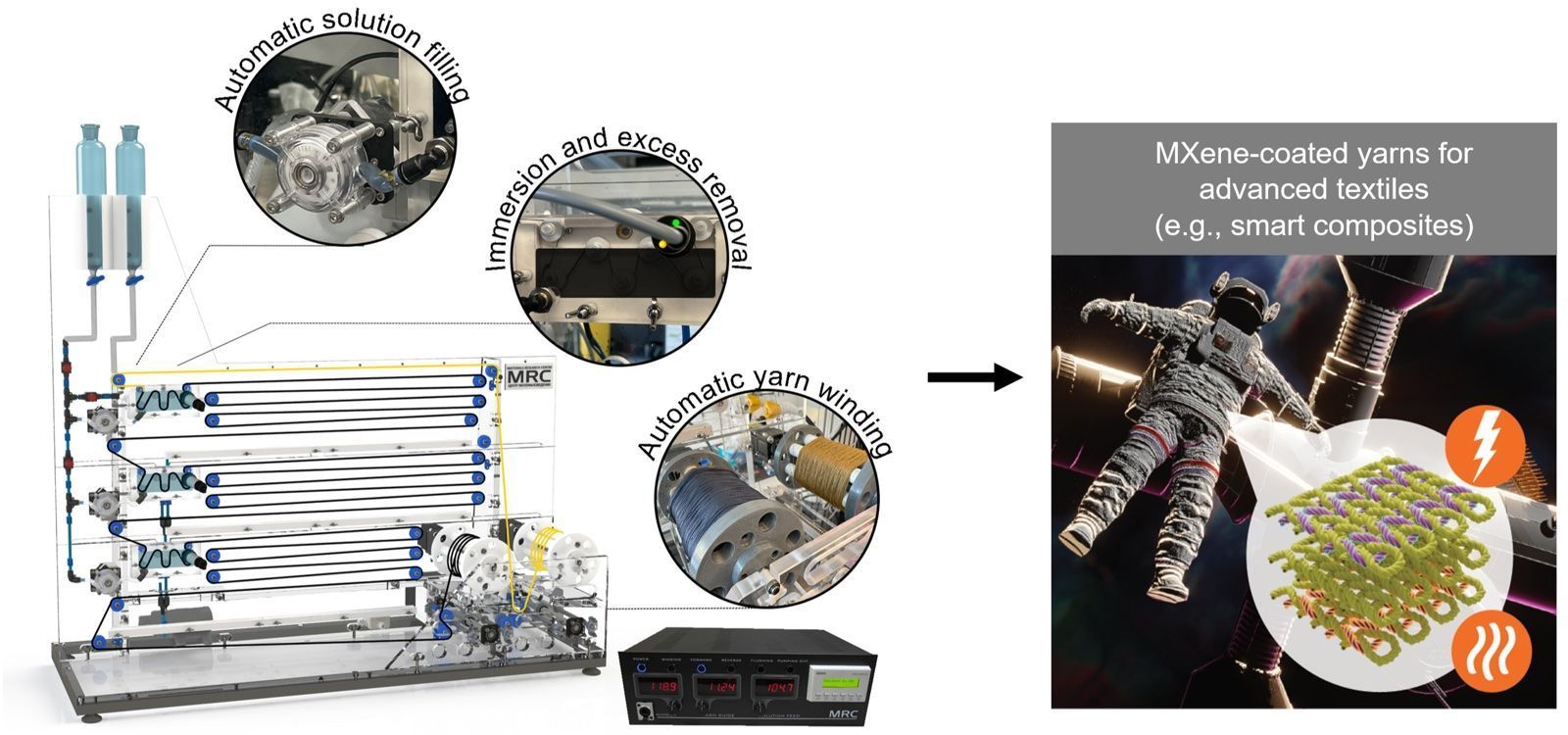

Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved. Congratulations to all collaborators with this interesting joint work!

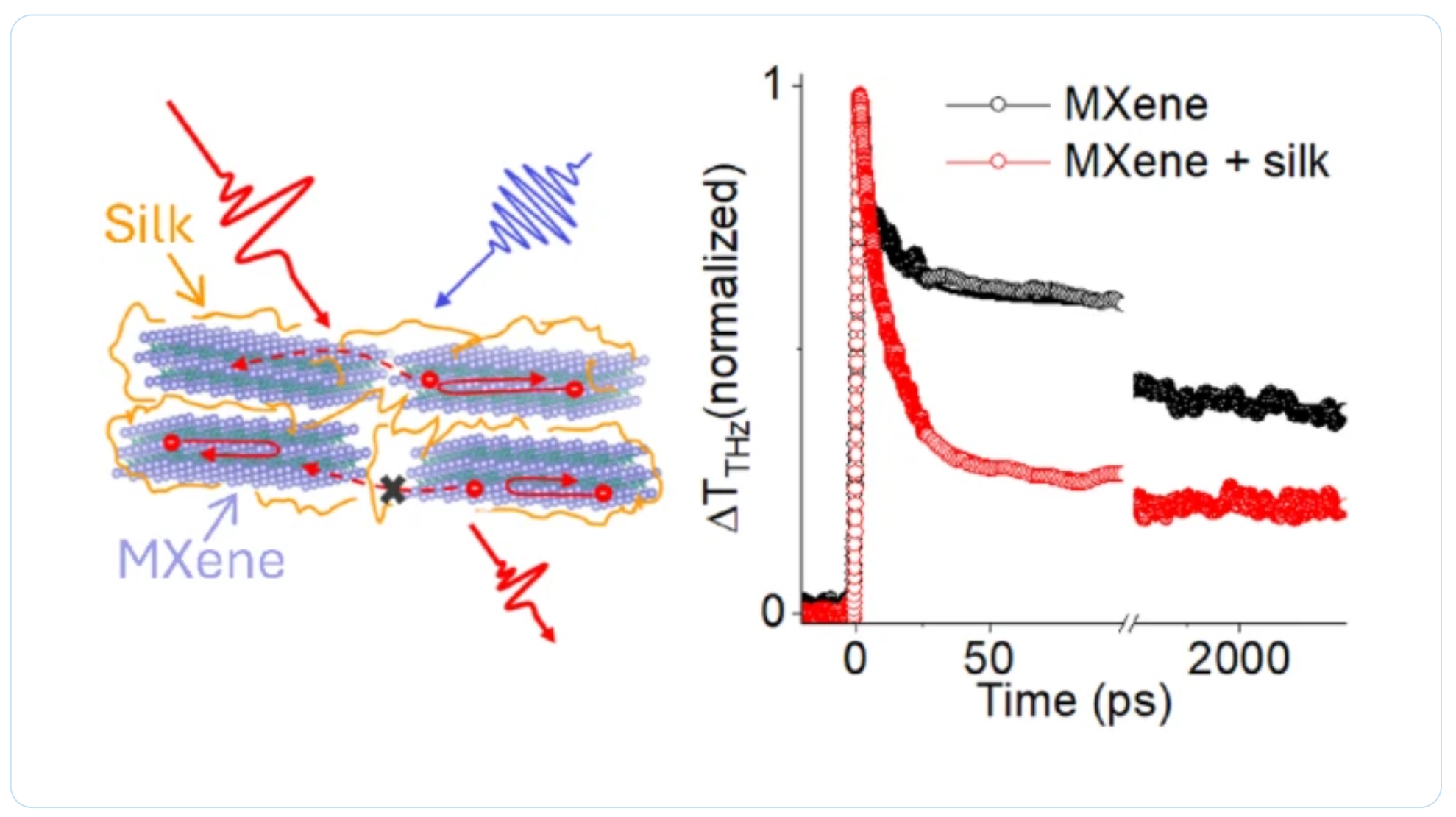

Congratulations to all collaborators with this interesting joint work! Thank you to our collaborators for the amazing joint work recently published in Graphene and 2D Nanomaterials about MXene–silk fibroin composite films aiming to develop materials with tunable electronic and thermal properties

Thank you to our collaborators for the amazing joint work recently published in Graphene and 2D Nanomaterials about MXene–silk fibroin composite films aiming to develop materials with tunable electronic and thermal properties Dr. Oleksiy Gogotsi, director of MRC and Carbon-Ukraine, innovative companies that are among the leaders on the world MXene market, visited 2024 MRS Fall Meeting & Exhibit. together with Dr. Maksym Pogorielov, Head of Advanced Biomaterials and Biophysics Laboratory, University of Latvia.

Dr. Oleksiy Gogotsi, director of MRC and Carbon-Ukraine, innovative companies that are among the leaders on the world MXene market, visited 2024 MRS Fall Meeting & Exhibit. together with Dr. Maksym Pogorielov, Head of Advanced Biomaterials and Biophysics Laboratory, University of Latvia.

MRC and Carbon-Ukraine team visited the 3rd International MXene conference held at Drexel University on August 5-8, 2024. Conference brought together the best reserchers and leading experts on MXene field.

MRC and Carbon-Ukraine team visited the 3rd International MXene conference held at Drexel University on August 5-8, 2024. Conference brought together the best reserchers and leading experts on MXene field.

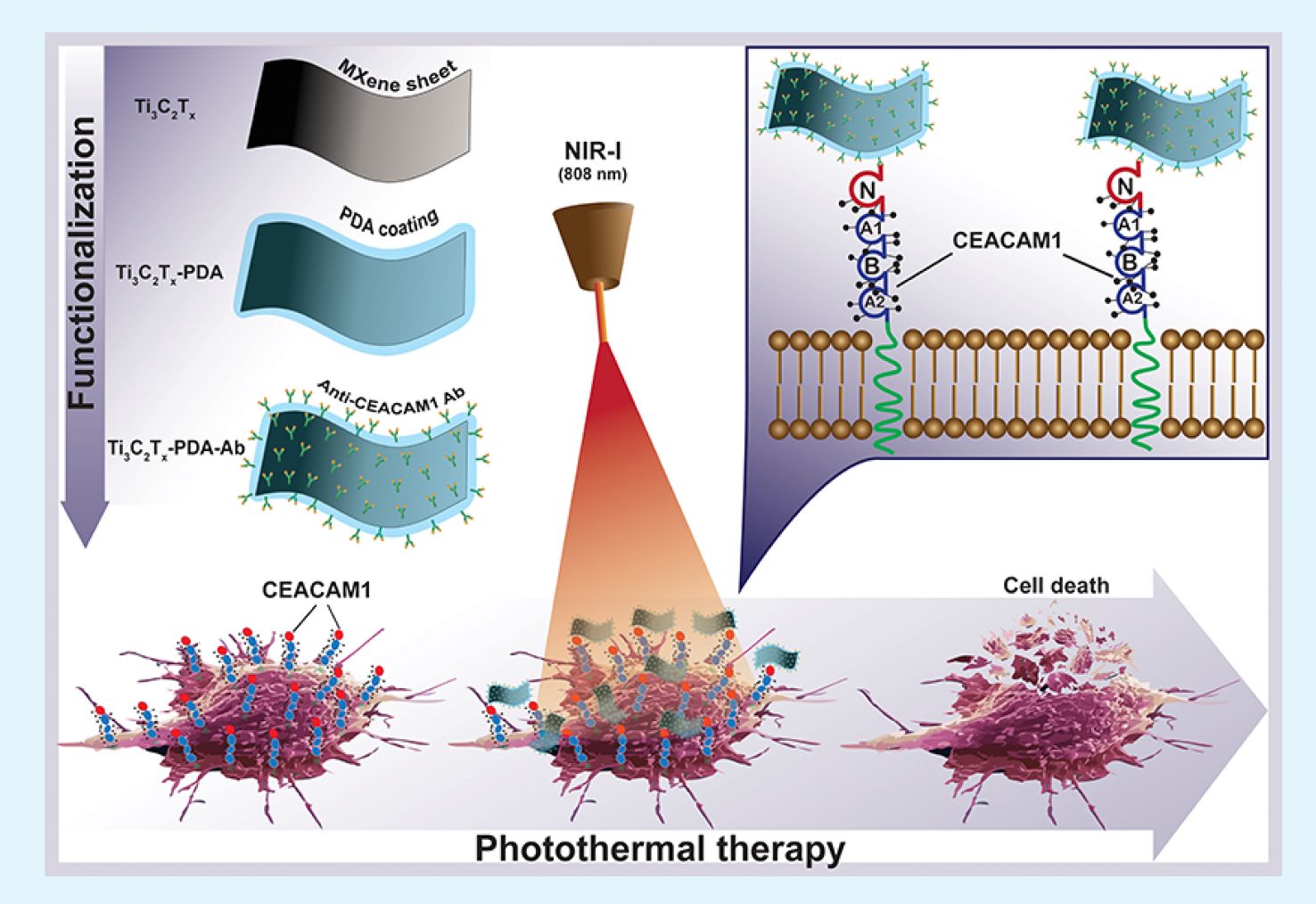

Together with colleagues from the University of Latvia, MRC/Carbone Ukraine, Adam Mickiewicz University, University Clinic Essen, and others, we have developed a novel concept involving the binding of antibodies to MXenes. In our research, we utilized anti-CEACAM1 antibodies to develop targeted photo-thermal therapy for melanoma (in vitro), paving the way for future in vivo studies and clinical trials. For the first time, we demonstrate the feasibility of delivering MXenes specifically targeted to melanoma cells, enabling the effective ablation of cancer cells under near-infrared (NIR) light. This new technique opens up vast potential for the application of MXenes in cancer treatment, diagnostics, drug delivery, and many other medical purposes.

Together with colleagues from the University of Latvia, MRC/Carbone Ukraine, Adam Mickiewicz University, University Clinic Essen, and others, we have developed a novel concept involving the binding of antibodies to MXenes. In our research, we utilized anti-CEACAM1 antibodies to develop targeted photo-thermal therapy for melanoma (in vitro), paving the way for future in vivo studies and clinical trials. For the first time, we demonstrate the feasibility of delivering MXenes specifically targeted to melanoma cells, enabling the effective ablation of cancer cells under near-infrared (NIR) light. This new technique opens up vast potential for the application of MXenes in cancer treatment, diagnostics, drug delivery, and many other medical purposes.

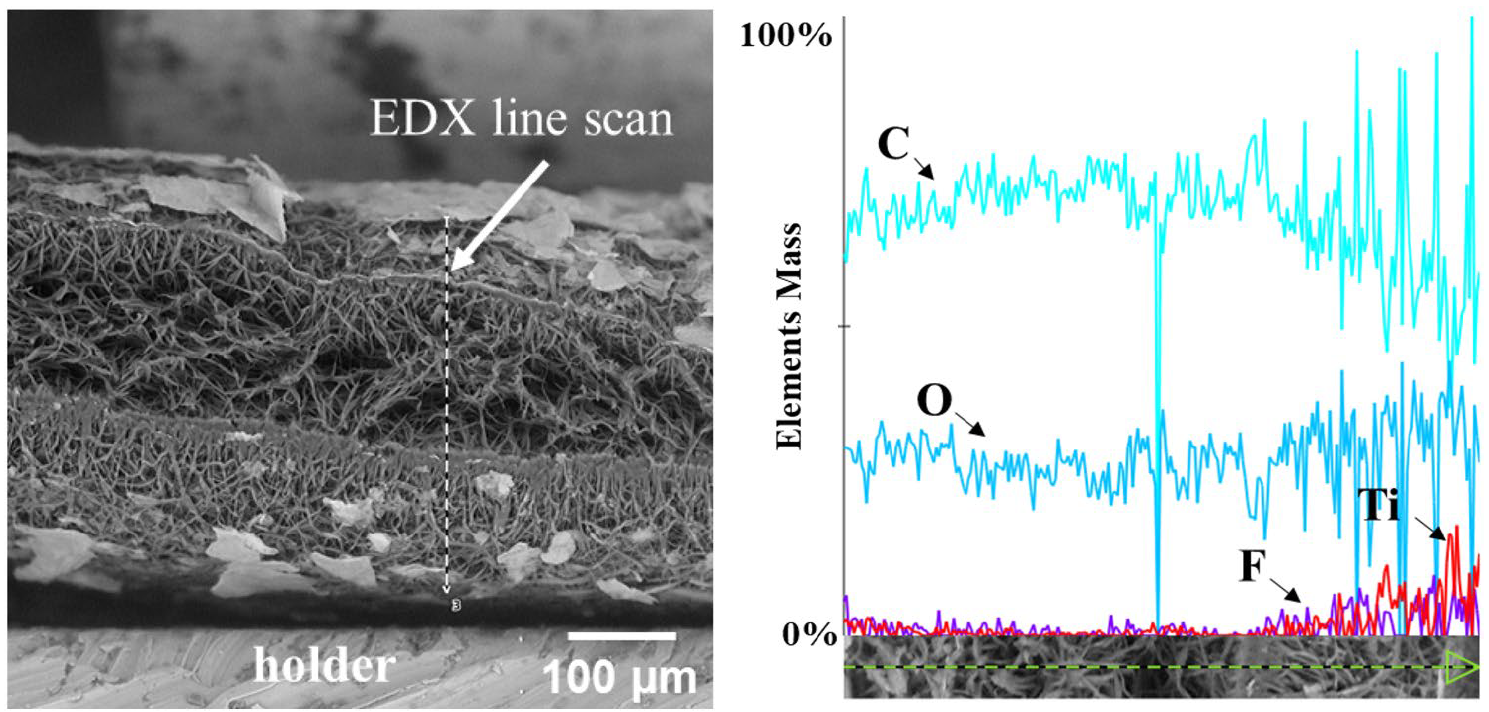

Here we demonstrate a new developed method for depositing Ti3C2Tx MXenes onto hydrophobic electrospun PCL membranes using oxygen plasma treatment. These novel patches hold tremendous potential for providing mechanical support to damaged heart tissue and enabling electrical signal transmission,thereby mimicking the crucial electroconductivity required for normal cardiac function. After a detailed investigation of scaffold-to-cell interplay, including electrical stimulation, novel technology has the potential for clinical application not only for cardiac regeneration, but also as neural and muscular tissue substitutes.

Here we demonstrate a new developed method for depositing Ti3C2Tx MXenes onto hydrophobic electrospun PCL membranes using oxygen plasma treatment. These novel patches hold tremendous potential for providing mechanical support to damaged heart tissue and enabling electrical signal transmission,thereby mimicking the crucial electroconductivity required for normal cardiac function. After a detailed investigation of scaffold-to-cell interplay, including electrical stimulation, novel technology has the potential for clinical application not only for cardiac regeneration, but also as neural and muscular tissue substitutes.

MX-MAP project participants from MRC Dr. Oleksiy Gogotsi and Veronika Zahorodna performed split secondment visit to project partner organization University of Padova (Italy). MX-MAP project works on development of the key strategies for MXene medical applications.

MX-MAP project participants from MRC Dr. Oleksiy Gogotsi and Veronika Zahorodna performed split secondment visit to project partner organization University of Padova (Italy). MX-MAP project works on development of the key strategies for MXene medical applications.