12th International Ceramics Congress CIMTEC 2010, Montecatini Terme, Florence, Italy 6-18, June 2010

Montecatini Terme, Florence, Italy, on June 6 to 18, 2010 hosts the 12th International Conference on Modern Materials and Technologies - CIMTEC 2010.

CIMTEC 2010 will consist of the 12th International Ceramics Congress (June 6-11) and of the 5th Forum on New Materials (June 13-18), each of them including a number of Symposia, Focused Sessions, and Conferences. CIMTEC again gathers together many qualified materials scientists, physicists, chemists and engineers as well as experts of a wide range of the most demanding application areas of modern materials, from information technology to biological systems. CIMTEC 2010 devotes special attention to most relevant directions for materials research based on new theory and refined modeling strategies and on the ever increasing opportunities offered by the continuous remarkable progress in nanoscience and nanotechnology. Outstanding areas of the subject covers from the molecular and nanoscales to large complex integrated systems. Special focus of the Forum on New Materials will be to apply the new research findings to the development of a number of sustainable energy technologies from advanced fossil fuel energy cycles including CO2 sequestration, to nuclear energy, to photovoltaic power generation.

CIMTEC 2010 will consist of the 12th International Ceramics Congress (June 6-11) and of the 5th Forum on New Materials (June 13-18), each of them including a number of Symposia, Focused Sessions, and Conferences. CIMTEC again gathers together many qualified materials scientists, physicists, chemists and engineers as well as experts of a wide range of the most demanding application areas of modern materials, from information technology to biological systems. CIMTEC 2010 devotes special attention to most relevant directions for materials research based on new theory and refined modeling strategies and on the ever increasing opportunities offered by the continuous remarkable progress in nanoscience and nanotechnology. Outstanding areas of the subject covers from the molecular and nanoscales to large complex integrated systems. Special focus of the Forum on New Materials will be to apply the new research findings to the development of a number of sustainable energy technologies from advanced fossil fuel energy cycles including CO2 sequestration, to nuclear energy, to photovoltaic power generation.

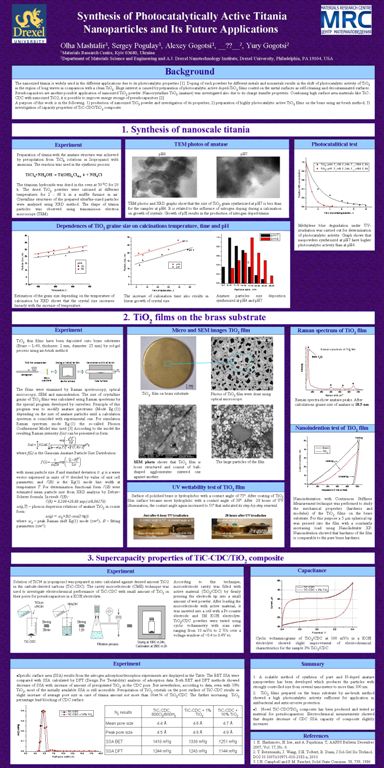

Alexey Gogotsi represented Materials Research Centre at CIMTEC 2010 with a poster presentation on Nanomanufactoring in Disсlosing Materials at Nanoscale: Synthesis and Applications of Photocatalytically Active Titania Nanoparticles / O. Mashtalir, S. Pogulay, A. Gogotsi, Materials Research Centre,Kiev 03680, Ukraine; M. Curtoglu, K. Perez, Y. Gogotsi, Drexel University, Philadelphia, PA 19104, USA.

Abstract

Titania nanoparticles are widely used in photocatalysis, solar cells,pseudocapacitors and other applications. This report is on a scalable method of synthesis of pure and nitrogen-doped anatase nanopowders with the particle size from several nanometers to more than 100 nm, which can be controlled by the process parameters. Preparation of nanosized titanium dioxide with the anatase structure was achieved by precipitation from solutions with subsequent calcinations. The reaction of the isopropanol solution of titanium tetrachloride with ammonia was used in the synthesis process. The effects of the process parameters (pH, temperature and time of calcinations) on the phase composition, particle size, color and morphology have been studied using XRD, Raman spectroscopy and TEM. Nitrogen doping leads to yellow powders. It is important to stress that titanium chloride produced as a chemical industry waste was used in this process. Nanosized TiO2 prepared by this method shows a strong photocatalytic activity. The prepared titania solutions were found to very active to degrade solutions of Methylene blue, Methyl Red and colored household chemicals under UVA light.

A symposium organizer, speaker, and member of the International Advisory Committee for CIMTEC 2010 -12th International Conference on Modern Materials and Technologies Y.Gogotsi, Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute, at the CIMTEC 2010 made an oral presentation

Nanostructured Titania Films with Improved Photocatalytic Activity / Y.Gogotsi, M.Curtoglu, T.Longenbach, Departament of Materials Science and Engineering, A.J. Drexel Nanotechnology Institute, Drexel University Philadelphia, PA 19104, USA.

Abstract

Photocatalytic properties of titanium dioxide (titania) have attracted much attention within the last decade due to titania’s photochemical stability and high efficiency. Being a cheap, readily available, and biocompatible material, TiO2 is particularly suitable for use in the large- scale production on light activated films on the surfaces of self-cleaning glassware, air and water purification systems, and self-sterilizing material. In order to increase the effectiveness of these films, we have explored the effects of dopingnanostructured TiO2 films with various elements that can dissolve in the titania lattice without a significant strain, particularly those which have ionic radiuses similar to that of titanium. A sol-gel process was implemented for the preparation of doped TiO2 films on glass and the experimental results were supported by the density functional theory (DFT). It has been shown that it is possible to significantly increase the photocatalytic activity of TiO2 by carefully selecting the experimental conditions and film composition.

Professor George A. Gogotsi, Institute for Problems of Strength, Ukraine, took part in Session on Refractories: Recent Developments in Materials, Production and use, with a oral presentation

Fracture Resistance Investigations of Refractory Materials, George Gogotsi, Pisarenko Institute for Problems of Strength, Kiev, Ukraine.

Abstract

Advanced oxide and nonoxide refractory materials were tested by edge flaking with different standard diamond indenters. Fracture resistance characteristic obtained with the Rockwell indenter (named FR) was calculated from results of direct measurements that did not make use of linear fracture mechanics concepts, which is typical of fracture toughness determinations. It is proportional to the Kc values measured by the single edge V-notched beam (SEVNB) method. The discussed edge fracture (EF) method enables the determination of fracture resistance of ceramics in small-size specimen tests. It has been demonstrated that the EF test method can be quite adequate for enhancing the reliability of comparative fracture resistance estimates and was appropriate for evaluating the uniformity of refractory material items by their fracture resistance. Such tests with small size specimens can be performed on the equipment available in a conventional mechanical laboratory. The EF method may also be employed for studying the localized mechanical behaviour of the material on the edges of the items.

|

|

| Professor George Gogotsi, Institute for Problems of Strength and Alexey Gogotsi, Materials Research Centre, and Eugeniy Dianov, Director of the Fiber Optics Research Center, Institute of General Physics at the CIMTEC 2010 | Alexey Gogotsi, Materials Research Centre, with a poster presentation, at the CIMTEC 2010 |

|

|

| Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute Y.Gogotsi at the CIMTEC 2010 | Opening Session of the 12th International Ceramics Congress CIMTEC 2010 |

|

|

| Yury Gogotsi, Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute,USA,CIMTEC 2010, Montecatini Terme, Florence, Italy | Professor George A.Gogotsi at the 12th International Ceramics Congress with Professor Marc Huger, GEMH, Limoges-France |

|

|

| Alexey Gogotsi at the Poster Session Holl | Alexey Gogotsi,Director of the Materials Research Centre, Ukraine, Yury Gogotsi, Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute,USA,Professor George A.Gogotsi, Institute for Problems of Strength, Ukraine |

|

|

| Alexey Gogotsi,Director of the Materials Research Centre, Ukraine, Maxim Ivanov,Ural Department of the Institute of Electrophysics RAS | Poster Session: Alexey Gogotsi, Director of the Materials Research Centre, Ukraine, Yury Gogotsi, Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute,USA,Professor George A.Gogotsi, Institute for Problems of Strength, Ukraine |

|

|

| Poster Session: Professor Michel Barsoum, A. W.Grosvenor Professor of Materials Science and Engineering Departament, A.J. Drexel Nanotechnology Institute,USA; Yury Gogotsi, Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute,;Alexey Gogotsi,Director of the Materials Research Centre | 12th International Ceramics Congress CIMTEC 2010, from left to right :Volker Presser, Post-Doctoral Researcher, A.J. Drexel Nanotechnology Institute, Alexey Gogotsi, Director of the Materials Research Centre, Ukraine, Prof. Klaus G. Nickel,Tubingen University, Germany |

|

|

| Michel Barsoum, A. W.Grosvenor Professor of Materials Science and Engineering Departament, A.J. Drexel Nanotechnology Institute,USA), Yury Gogotsi, Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute), Alexey Gogotsi, Director of Materials Research Centre , Ukraine, discussed Poster Presentation on Session CM: Disсlosing Materials at Nanoscale | From left to right : Michel Barsoum, A. W.Grosvenor Professor of Materials Science and Engineering Departament, A.J. Drexel Nanotechnology Institute,USA), Yury Gogotsi, Trustee Chair Professor of Materials Science and Engineering Director, A.J. Drexel Nanotechnology Institute), Alexey Gogotsi, Director of Materials Research Centre , Ukraine |

|

|

| Professor David W. Marshall, Teledyne Scientific, CA, USA and Professor George A.Gogotsi, Institute for Problems of Strength, Ukraine | 12th International Ceramics Congress CIMTEC 2010 dinner |

|

|

| In the Presidium:Dr.Pietro Vincenzini, Chairman of Council of THE WORLD ACADEMY OF CERAMICS, Chairman of Board THE TECHNA GROUP, General Chair of THE CIMTEC Conferences, General Editor of the international journal CERAMICS INTERNATIONAL, and representative of the Italian Government and representative of the Italian Government | Farewell dinner of The 12th International Ceramics Congress CIMTEC 2010 |

|

|

| Alexey Gogotsi, Director of MRC, Kiev,Ukraine with Prof. Rajendra Bordia , University of Washington, USA | Alexey Gogotsi, Director of MRC,Ukraine, with Dr.Nina Orlovskaya, University of Central Florida,USA |

|

|

| Dr. Elizabeth Opila, NASA Glenn Research Center, USA with Alexey Gogotsi, Director of Materials Research Centre | Alexey Gogotsi, Materials Research Centre, with Dr.Pietro Vincenzini, Chairman of Council of THE WORLD ACADEMY OF CERAMICS, General Chair of THE CIMTEC Conferences |

|

Director of Materials Research Centre Alexey Gogotsi with K. Byrappa, University of Mysor, India |

Oral presentations:

Stability of Oxides In High Temperature Water Vapor E.J. Opila, Nasa Glenn Research Center, Cleveland, OH, USA

The Max Phases Ductile, Machinable Ternary Carbides and Nitrides for High Temperature and Other Applications. M.W. Barsoum , Dept. of Materials Science and Engineering, Drexel University, Philadelphia, PA, USA

Characterization of Wear Mechanisms of Silicon Carbide Materials V. Presser, K.G. Nickel, C. Berthold , Eberhard-Karls-Universitat Tubingen, Inst for Geosciences, Applied Mineralogy, Tubingen, Germany

Ceramic Composites for High Temperature Propolsion System D.B. Marshall, Teledyne Scientific,CA, USA

Processing of Ceramic Coatings and Myltilayered Ceramics R.Bordia University of Washington, Seattle, WA, USA

Bi-doped Glass Optical Fibers: Properties and Applications, E. Dianov,Fiber Optics Research Center, Moscow, Russia

Production of Nanopowders with the Help of Fiber Laser M.Ivanov, Yu. Kotov, O.Samatov, Institute of Electrophusics, Ural Division of Russian Academy of Sciences, Russia

Thermo-mechanical Characterization of Scandia and Ceria Doped Circonia- Electrolyte Material for Intermediate Temperature Solid Oxide Fuel Cells N. Orlovskaya, University of Central Florida, USA, W.Lim, M.Radovic Texas AM University,USA, T.Graule, J.Kuebler EMPA Swiss Federal Laboratories for Materials Testing and Research, Switzerland

Novel Hydrothermal Solution Routes of Advanced Nanomaterials and Nanoceramics Processing K.Byrappa DOS in Geology, University of Mysore, Mysore,India

Read more : СIMTEC 2010

International conferences and symposiums on the site of Materials Research Centre

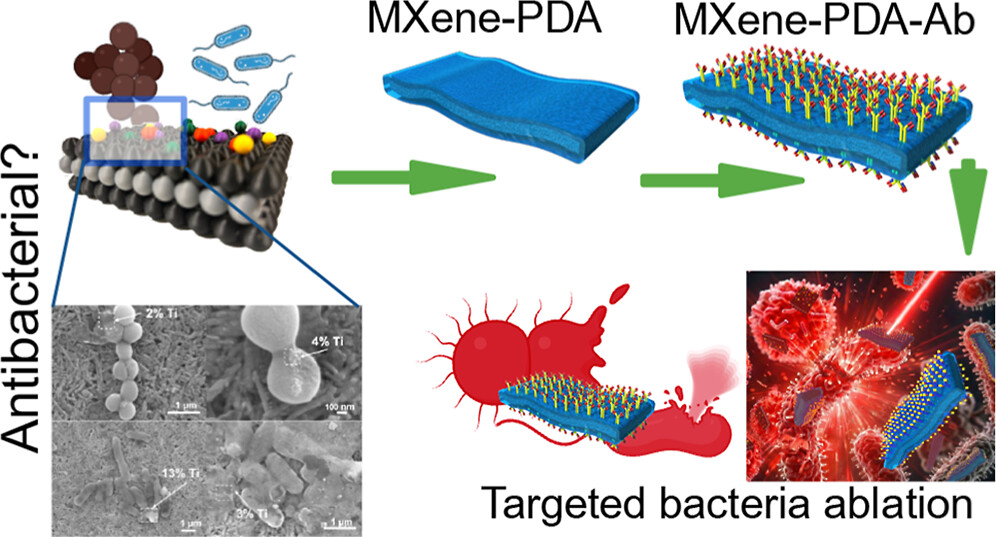

Do MXene nanosheets possess intrinsic antibacterial activity? A systematic study of high-quality Ti-, V-, and Nb-based MXenes reveals negligible inherent antimicrobial effects while highlighting their strong potential for targeted photothermal antibacterial therapy.

Do MXene nanosheets possess intrinsic antibacterial activity? A systematic study of high-quality Ti-, V-, and Nb-based MXenes reveals negligible inherent antimicrobial effects while highlighting their strong potential for targeted photothermal antibacterial therapy. Highlights

Highlights We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development.

We are excited to share that our Carbon-Ukraine (Y-Carbon LLC) company participated in the I2DM Summit and Expo 2025 at Khalifa University in Abu-Dhabi! Huge thanks to Research & Innovation Center for Graphene and 2D Materials (RIC2D) for hosting such a high-level event.It was an incredible opportunity to meet brilliant researchers and innovators working on the next generation of 2D materials. The insights and energy from the summit will definitely drive new ideas in our own development. Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments.

Carbon-Ukraine team had the unique opportunity to visit XPANCEO - a Dubai-based deep tech startup company that is developing the first smart contact lenses with AR vision and health monitoring features, working on truly cutting-edge developments. Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

Our Carbon-Ukraine team (Y-Carbon LLC) are thrilled to start a new RIC2D project MX-Innovation in collaboration with Drexel University Yury Gogotsi and Khalifa University! Amazing lab tours to project collaborators from Khalifa University, great discussions, strong networking, and a wonderful platform for future collaboration.

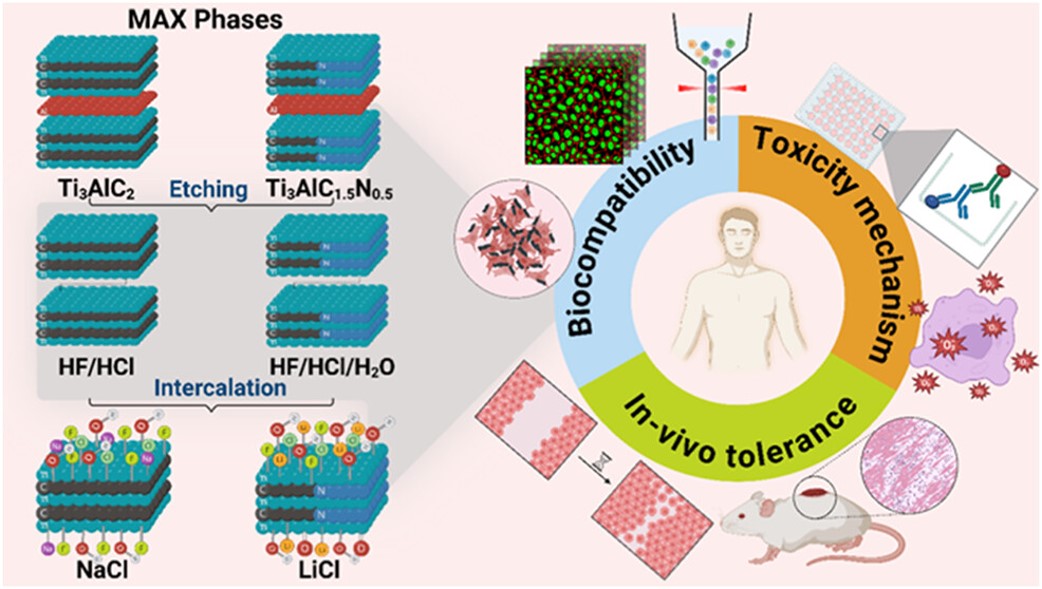

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications.

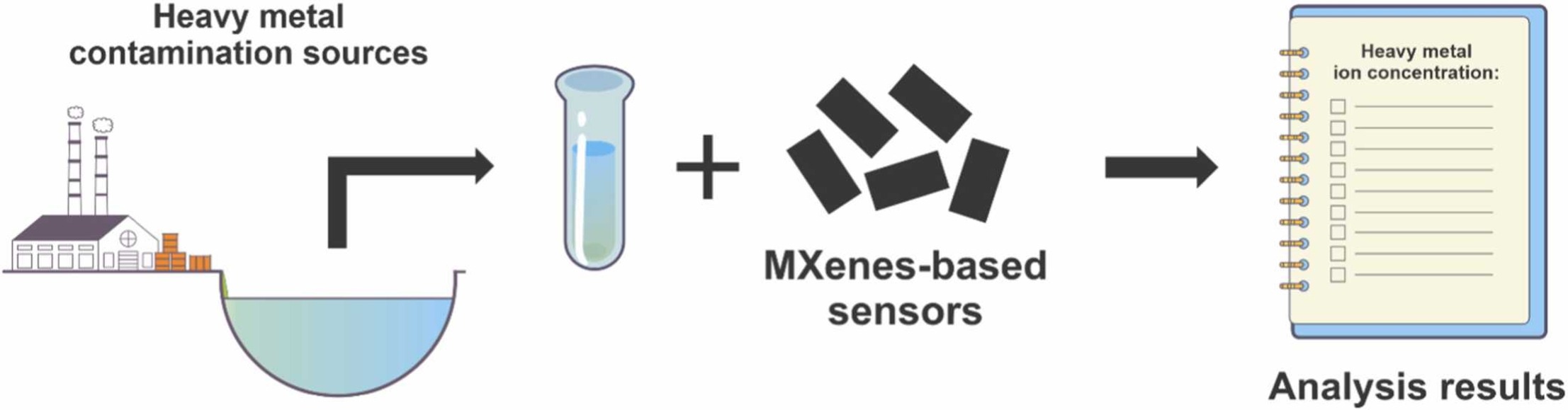

MXenes potential applications include sensors, wound healing materials, and drug delivery systems. A recent study explored how different synthesis methods affect the safety and performance of MXenes. By comparing etching conditions and intercalation strategies, researchers discovered that fine-tuning the surface chemistry of MXenes plays a crucial role in improving biocompatibility. These results provide practical guidelines for developing safer MXenes and bring the field one step closer to real biomedical applications. An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

An excellent review highlighting how MXene-based sensors can help tackle one of today’s pressing environmental challenges — heavy metal contamination. Excited to see such impactful work moving the field of environmental monitoring and sensor technology forward!

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme.

Carbon-Ukraine team was truly delighted to take part in the kickoff meeting of the ATHENA Project (Advanced Digital Engineering Methods to Design MXene-based Nanocomposites for Electro-Magnetic Interference Shielding in Space), supported by NATO through the Science for Peace and Security Programme. Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved!

Exellent news, our joint patent application with Drexel University on highly porous MAX phase precursor for MXene synthesis published. Congratulations and thanks to all team involved! Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!

Our team was very delighted to take part in International Symposium "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene event in Europe this year!  Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field!

Last Call! Have you submitted your abstract for IEEE NAP-2025 yet? Join us at the International Symposium on "The MXene Frontier: Transformative Nanomaterials Shaping the Future" – the largest MXene-focused conference in Europe this year! Final Submission Deadline: May 15, 2025. Don’t miss this exclusive opportunity to showcase your research and engage with world leaders in the MXene field! We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A.

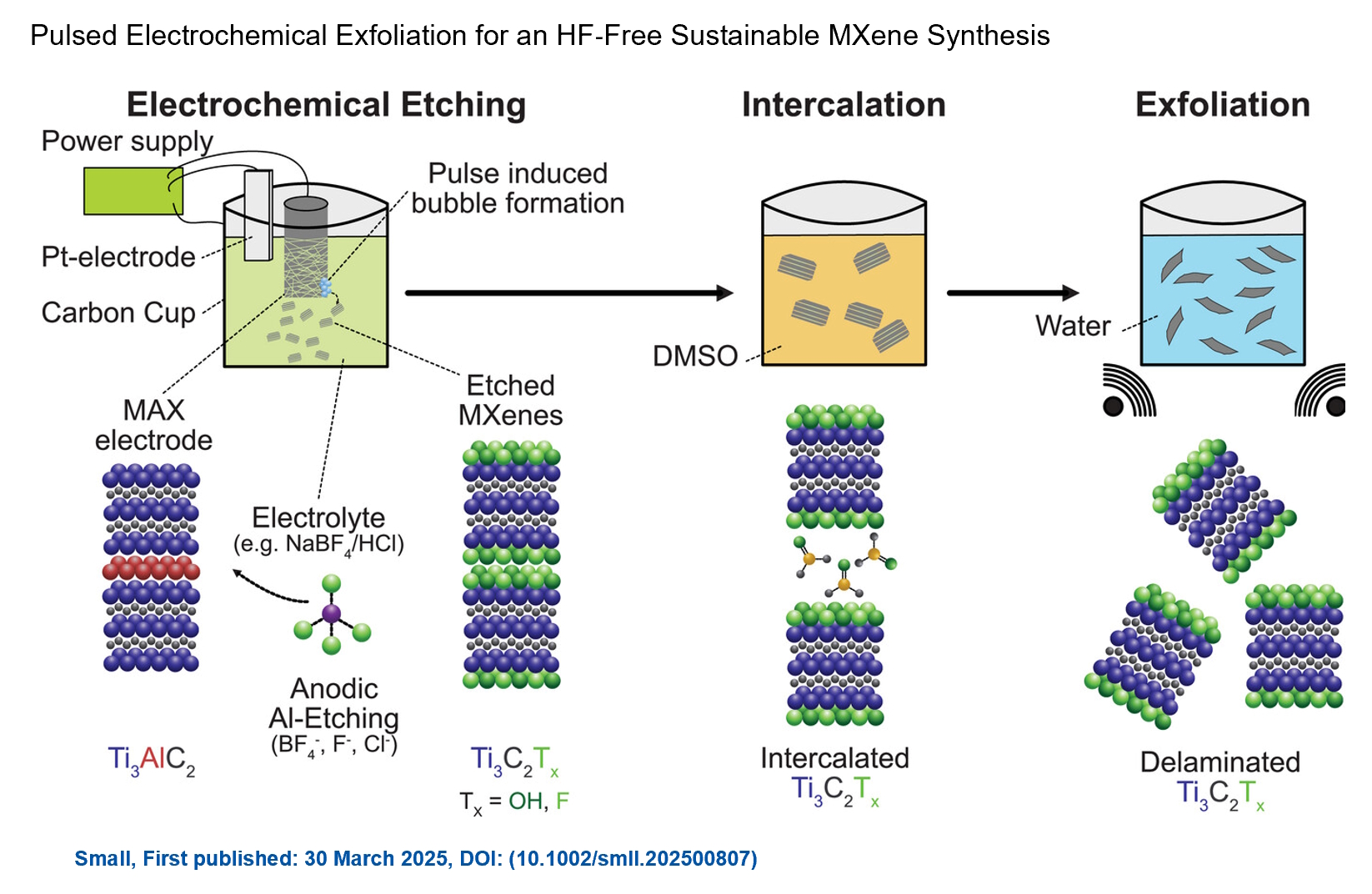

We are excited to announce the publication of latest review article on MXenes in Healthcare. This comprehensive review explores the groundbreaking role of MXenes—an emerging class of 2D materials—in revolutionizing the fields of medical diagnostics and therapeutics. Read the full article here: https://doi.org/10.1039/D4NR04853A. Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.

Congratulations and thank you to our collaborators from TU Wien and CEST for very interesting work and making it published! In this work, an upscalable electrochemical MXene synthesis is presented. Yields of up to 60% electrochemical MXene (EC-MXene) with no byproducts from a single exfoliation cycle are achieved.