Capacitance of coarse-grained carbon electrodes with thickness up to 800 μm

Liying Liu a, Xuehang Wang b, Vladimir Izotov a,c, Dmytro Havrykov a, Illia Koltsov a, Wei Han a,c, Yulia Zozulya d, Olga Linyucheva d, Veronika Zahorodna d,e, Oleksiy Gogotsi d,e, Yury Gogotsi a,b

a Key Laboratory of Physics and Technology for Advanced Batteries (Ministry of Education), College of Physics, Jilin University, Changchun 130012, PR China

b A. J. Drexel Nanomaterials Institute, Department of Materials Science and Engineering, Drexel University, Philadelphia, PA 19104, United States

c International Center of Future Science, Jilin University, Changchun, 130012, PR China

d Materials Research Center, Kiev 03680, Ukraine

e National Metallurgical Academy of Ukraine, Dnipro 49600, Ukraine

Electrochimica Acta ( IF 5.116 ) Pub Date : 2019-02-05 , DOI: 10.1016/j.electacta.2019.02.004

https://doi.org/10.1016/j.electacta.2019.02.004

Highlights:

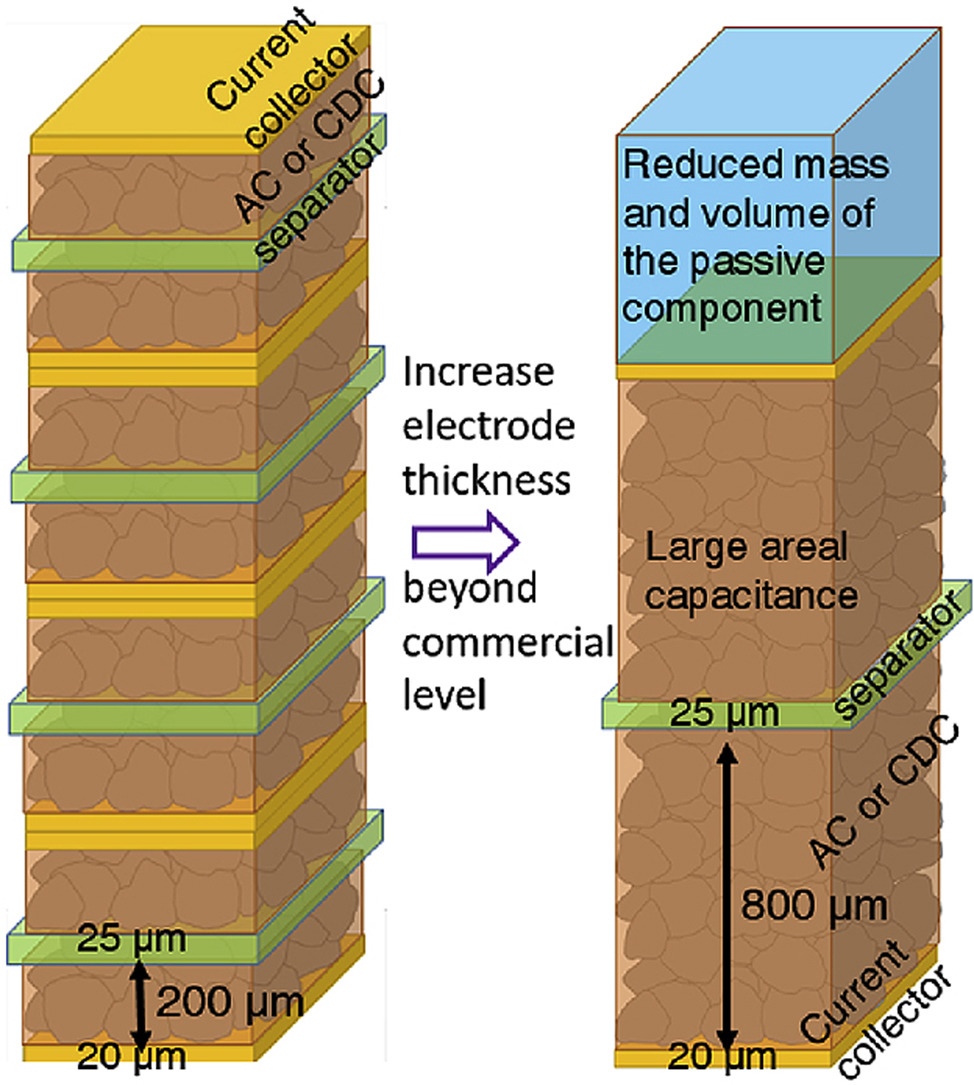

• The capacitance retention of coarse-grained AC is above 80 % as the electrode thickness increases from 200 to 800 µm.

• The mass and volume occupied by passive components are reduced with the increased mass loading of the active material.

• A strategy improves the energy density of supercapacitor without extra cost or changing the current manufacturing process.

Abstract

Increasing the mass loading of active material in a supercapacitor electrode improves the energy storage capability per electrode area. However, the increase of mass loading is accompanied by the increased electrode thickness, which often causes drops in specific capacitance and counteracts the potential increase in areal capacitance once the electrode thickness exceeds 100 mm. In our previous work, we showed high specific capacitance retention of coarse-grained carbide derived carbon (CDC) with electrode thicknesses up to 1000 mm in organic electrolytes. In this work, we report that this behavior can be extended to coarse-grained activated carbon (AC).

AC is the most common commercial supercapacitor electrode material with a much broader pore size distribution and lower electric conductivity compared to CDC. The areal capacitance of the AC electrode is enhanced from 2.3 F/cm2 to 7.4 F/cm2 at 5 mV/s, as the electrode thickness increases from 200 to 800 mm. With the increased mass loading of the active electrode material, the mass and volume occupied by current collectors and separators are reduced in the electrode stack, which leads to an increase of the gravimetric and volumetric energy density of the device. By reporting on this advantageous behavior in thick electrodes using coarse-grained carbons, we hope to garner interest toward an unexplored method for improving the performance of porous carbonbased supercapacitors, without increasing the cost or changing the current used supercapacitor manufacturing process.

https://www.sciencedirect.com/science/article/pii/S0013468619302294#undfig1